Driving a broom round the factory floor

Driving everyone up the wall you mean ![]()

He’s carried on that job into retirement too ![]()

Graham, the test fleet trucks are built using hand picked parts, all the loose parts will be hand picked to find the ones with the tightest tolerances. Once assembled they will be carefully run in on the bench before going in the chassis. Tyres are buffed down to get the lowest rolling resistance, extremely light weight oils are used, they all have the best aerodynamic options available, they’ll usually run direct top gearing, they’ll have the highest flow rate fuel filters and things that you and I probably wouldn’t think of in a hundred years.

They may even have a bit of trickery like ported and polished manifolds and high flow exhausts, but that’s only my own thoughts. I would certainly do it all if I was running a press fleet, it’s not cheating, just making the best of what you’ve got.

Their drivers look after them very well. They put lots of miles on them to ensure everything is as it should be and monitor everything very closely.

That’s not a problem. Apart from the handbuilt engines, all the other procedures are available to the end user.

Attempting to get false readings is cheating. As I remember the vehicle in question was thrown off the test. The management denied all knowledge of wrong doing and the engineers were never let out in public again. How true that is nobody will ever know, but to make allegations that ABC manufacturers were trying to cheat is inviting a lawsuit that would put a magazine out of business, even small manufacturers like Dennison would have more financial clout (& better lawyers) than a magazine would. Goliath would always give David a beating in a case like that.

newmercman:

Graham, the test fleet trucks are built using hand picked parts, all the loose parts will be hand picked to find the ones with the tightest tolerances. Once assembled they will be carefully run in on the bench before going in the chassis. Tyres are buffed down to get the lowest rolling resistance, extremely light weight oils are used, they all have the best aerodynamic options available, they’ll usually run direct top gearing, they’ll have the highest flow rate fuel filters and things that you and I probably wouldn’t think of in a hundred years.They may even have a bit of trickery like ported and polished manifolds and high flow exhausts, but that’s only my own thoughts. I would certainly do it all if I was running a press fleet, it’s not cheating, just making the best of what you’ve got.

Their drivers look after them very well. They put lots of miles on them to ensure everything is as it should be and monitor everything very closely.

That’s not a problem. Apart from the handbuilt engines, all the other procedures are available to the end user.

Attempting to get false readings is cheating. As I remember the vehicle in question was thrown off the test. The management denied all knowledge of wrong doing and the engineers were never let out in public again. **How true that is nobody will ever know, but to make allegations that ABC manufacturers were trying to cheat is inviting a lawsuit that would put a magazine out of business, even small manufacturers like Dennison would have more financial clout (& better lawyers) than a magazine would. Goliath would always give David a beating in a case like that.[/**quote]

How very true. I was once a witness in a case many years ago where the defendant was as guilty as hell, but because he had money he could afford a top barrister and got off. Everyone knew he was guilty as charged, but you can buy a non-guilty verdict if you have money.

newmercman:

Graham, the test fleet trucks are built using hand picked parts, all the loose parts will be hand picked to find the ones with the tightest tolerances. Once assembled they will be carefully run in on the bench before going in the chassis. Tyres are buffed down to get the lowest rolling resistance, extremely light weight oils are used, they all have the best aerodynamic options available, they’ll usually run direct top gearing, they’ll have the highest flow rate fuel filters and things that you and I probably wouldn’t think of in a hundred years.They may even have a bit of trickery like ported and polished manifolds and high flow exhausts, but that’s only my own thoughts. I would certainly do it all if I was running a press fleet, it’s not cheating, just making the best of what you’ve got.

Their drivers look after them very well. They put lots of miles on them to ensure everything is as it should be and monitor everything very closely.

That’s not a problem. Apart from the handbuilt engines, all the other procedures are available to the end user.

Attempting to get false readings is cheating. As I remember the vehicle in question was thrown off the test. The management denied all knowledge of wrong doing and the engineers were never let out in public again. How true that is nobody will ever know, but to make allegations that ABC manufacturers were trying to cheat is inviting a lawsuit that would put a magazine out of business, even small manufacturers like Dennison would have more financial clout (& better lawyers) than a magazine would. Goliath would always give David a beating in a case like that.

Selecting parts to assemble an optimally-performing engine, even if all of those parts are off production tools and within drawing tolerances, is cheating. It crosses the line because the assembled engine will be unrepresentative of the factory’s output. Testing a few engines on the dynamometer, and fitting the one with the best specific fuel consumption, may be less of a crime, given that all of the other variables you mention- tyres, running-in etc.- are optimised and monitored assiduously by mechanics.

I remember reading a magazine report on the E320-engined Roadtrain. It said that it climbed Shap (the M6 route) almost as quickly as a 141, if I remember correctly. Would the Roadtrain’s more aerodynamic cab and faster gearchange have been worth another 65bhp? I think not. I think that vehicle probably had an E370 in it. Another magazine roadtest featured an operator’s vehicle, which returned mediocre fuel consumption. I guess that its new tyres would account for some of the shortfall, along with the row of spotlights mounted in front of the air deflector! I bet the salesmen working for the vehicle’s manufacturer got a bit of a dressing down for that- not ensuring that the magazine had a factory-prepared vehicle to test. The 141 that was the subject of the Truck Magazine Eurotest was reported to have run poorly and emitted excessive smoke:

Engines with poor part-load sfc. Hmm… ■■■■■■■ 14 litre? Detroit 2-stroke?

I’ve driven identical lorries with identical load weights on identical routes, but experienced different performance levels. I recall two identical AEC Mercury rigid flats, both 1968 ‘F’ plates and with chassis numbers that were within 100 of each other. One had been bought new by a small haulier and had the same driver for the first 3 years of its life, it was even parked up in the yard when he went on holiday. The other Mercury was bought second hand from a national high street shops chain (originally a box van). The first one performed far better than the second one and could climb some hills one gear higher than the second.

Best Ergomatic Cabbed-Lorry Model? PART 22.Page 34.TRUCKNETUK.

WHITSUNTIDE

WHITSUNTIDE Festival:Sunday,26th,May to Sunday,2nd June,2013 ![]()

Ramone wrote » Sun May 26, 2013 3:29 pm:-

CF, how can you say that the 3VTG cab would have been more successful than the Marathon when you know absolutely nothing about it ,all you know is what you`ve seen on here a few photos of a prototype that looked like a yank mounted on an AEC chassis for testing.You dont know what the ride was like ,the space inside, the visibility ,you know absolutely nothing whatsoever ,like most of your postings on here its either hindsight with your usual quote of history shows ,or just disagreement for the sake of it .I still cant quite make out why you compare the Marathon with the much higher powered F12 when it was the F10 which had a very similar output,maybe you wouldnt like the results of a test match between those 2.UNQUOTE.

VALKYRIE replies:- This is a refresher on what I wrote,and I will have to re-quote myself (it saves time and effort in re-writing it all again,anyway!):-

"Best Ergomatic Cabbed-Lorry Model? PART 4.Page 10.TRUCKNETUK

I’ll quote myself first:-

AEC SUPER MANDATOR V8 3VTG High Tower 6x4 PROTOTYPE CONCEPT PROJECT LORRY.

As I said in my last post,the wise AEC 3VTG Concept Project Lorry was the wise and inspired idea of the boss of AEC,Dr.Albert D.Fogg,who obviously wanted to copy Volvo with it’s refined American-style F88-F89 lorry models,and produce a refined American-style AEC heavy lorry range ![]() And in the words of the great Barry Norman:“And why not”…

And in the words of the great Barry Norman:“And why not”… ![]() And why not indeed,because other lorry manufacturers were doing the same thing

And why not indeed,because other lorry manufacturers were doing the same thing ![]()

The interior of the AEC 3VTG cab was well-appointed,with Bostrom Viking seats,a very comprehensive instrument panel and good cross cab access. The lorry’s engine bay allowed more air to circulate around the engine than with the Ergomatic Cab,and it’s AEC 801 Series V8 engine had a much larger header tank,radiator and cooling fan than the AEC Mandator V8.

Albert Fogg wanted to produce a better cab than the Ergomatic,and he was well on the way in doing this with his AEC 3VTG Lorry ![]() He realised that the Ergomatic was not big enough,it produced cooling problems for the engines,especially in the tropics,it had design flaws and,according to Albert Fogg,it was not suitable for long distance motorway journeys. So entered the AEC 3VTG Project-Concept-Prototype Heavy Lorry for all of the above reasons that I’ve listed

He realised that the Ergomatic was not big enough,it produced cooling problems for the engines,especially in the tropics,it had design flaws and,according to Albert Fogg,it was not suitable for long distance motorway journeys. So entered the AEC 3VTG Project-Concept-Prototype Heavy Lorry for all of the above reasons that I’ve listed ![]()

But,as I’ve already stated,Leyland mismanagement very misguidedly scrapped the AEC 3VTG Programme ![]() …and by doing so,it was yet another long,long,sharp,sharp nail in the unholy coffin of the British Leyland Motor Corporation!

…and by doing so,it was yet another long,long,sharp,sharp nail in the unholy coffin of the British Leyland Motor Corporation! ![]()

![]()

AEC SUPER MANDATOR V8 3VTG6RGAE 090 Mk1 High Tower Project-Concept-Prototype 6x4 Tractive Unit Specifications:-

Cab: Motor Panels Tilt Cab,modified.

Engine: AEC 801-Series-AVM8/801,13.1-Litre,V8 Diesel Engine,producing 272 BHP @ 2600 rpm,638 lbs ft of torque @ 1400 rpm.

Gearbox:Leyland-Self Changing Gears -SCG Pneumocyclic 10-forward speed Splitter Semi-Automatic Gearbox.

Rear driving axles: Leyland Group Hub Reduction Drive Axles.

Year:1968.

Not only was Dr.Albert D.Fogg the General Manager of AEC Ltd,he was a member of the board of the British Leyland Motor Corporation,Deputy Managing Director of this corporation and Director of Engineering of British Leyland. So his above various positions within British Leyland allowed him a substantial amount of influence within British Leyland and at AEC,thus,the AEC 3VTG being Albert Fogg’s pet project,he probably had every intention in eventually turning it in to a production lorry to take on the likes of the Volvo F88-F89,Scania LB110,etc ![]()

But of course,British Leyland mismanagement very misguidedly scrapped the 3VTG project ![]() ,which proved to be fatal for British Leyland in the long - as did the scrapping of the AEC marque!!!

,which proved to be fatal for British Leyland in the long - as did the scrapping of the AEC marque!!! ![]()

![]()

![]() .

.

According to Pat Kennett,development work started on the Leyland Marathon in circa 1971,and this lorry turned out to be a compromise because of the limited financial budget allotted for it’s development ![]() -

-

the AEC 3VTG would probably have been better and more successful than the Leyland-AEC Marathon ![]()

The Marathon was introduced in 1973. But instead of using the money for the Marathon project, AEC-Leyland might have saved some of this money getting rid of the V8 engine’s problems,fully developing the Motor Panels 3VTG cab and getting the AEC 3VTG heavy lorry range in to production,probably in 1972 ![]() It would not have been the compromise that the Marathon was."UNQUOTE.

It would not have been the compromise that the Marathon was."UNQUOTE.

If the AEC Super Mandator V8 3VTG High Tower PROTOTYPE was rough-riding,I’m sure that the ride would have been greatly improved for the production version,and,as I said in my Post 13,page 20:-

VALKYRIE:-"Albert Fogg’s AEC Super Mandator V8 3VTG High Tower 6x4 Tractive Unit,which looked like a Peterbilt High Tower COE,and was also in the same idiom as an Australian Atkinson High Tower COE,was designed for better engine cooling,better driver comfort and high power for long distance heavy duty freight trunking,and would have been for sale in British,European,Australian,New Zealand and other markets - as I said my PART 4:AEC and Albert Fogg were wisely doing a Volvo F88-F89! ![]()

![]() "

"

Since this was a prototype,and not a production example,it is fair to say that a production

version would have been moderately re-styled to look more English-European than American,while

also appealing to the Australian,New Zealand,etc,markets,who buy a lot of American heavy motor

trucks-lorries ![]() UNQUOTE.

UNQUOTE.

Carryfast wrote:-

The Germans in general have always been just average engineers compared to the Brits but somehow managed to invest loads more money in it’s industries especially in the post war years and it’s that investment which has always been reflected in it’s products.UNQUOTE.

VALKYRIE replies:-

Please correct me if I am wrong,but you seem to be a bit paranoid in regard to Leyland’s former

Director of Engineering,Dr-Ing Alfred Mueller,who was an excellent engineer,contibuted to Leyland

engineering in a positive way and was the mastermind of the radical rear-engined Leyland Atlantean Double Decker Bus and Motorcoach which was pace-setting and highly successful.

Imagine the year is 1963 (actually it’s a 2005 historic motor vehicle rally photograph),and here

are two conventional front - engined Leylands and a unconventional rear - engined Leyland Atlantean…but some time in the not too distant future,rear-engined motorcoaches and buses would become conventional ![]() l:-

l:-

LEYLAND ATLANTEAN PDR1/1/WEYMANN CH59F DOUBLE DECKER MOTORCOACH,RRN 428,Ribble 1279,1962,left.LEYLAND TITAN PD2/3/EAST LANCS FCL49RD MOTORCOACH,DCK 219,Ribble 1248,1951,right,and a Leyland Tiger PS1 or PS2 with the beautful archetypal Leyland appearance in the middle ![]() :-

:-

As I stated in Part 13,page 20,in this thread:-

THE GERMANS ARE VERY CLEVER ENGINEERS.

I have always admired the Germans in regard to their engineering know-how,innovation,invention

and perfectionism,the Germans are very clever,precise and intelligent engineers ![]() They have

They have

excelled in radio communications engineering,motor vehicle engineering,electrical engineering,

aerospace engineering,and so on ![]() And do not forget that a great German engineer-scientist,

And do not forget that a great German engineer-scientist,

Dr.Wernher Von Braun,who is one of my HEROES ![]() ,masterminded America’s highly successful space

,masterminded America’s highly successful space

programme,that included the Apollo men on the moon missions ![]() He is credited as being the “Father of Rocket Science”

He is credited as being the “Father of Rocket Science” ![]()

And the above objective facts reinforced with following statement from this linked website ![]() :-

:-

mygermancity.com/german-engineering

German Engineering Is A Leading Engine In Our World

German engineering seems to remain always in the champion division of the entire industry. As an example, this successful country maintains their great reputation as the top exporter of machinery and industrial equipment.

The quality is always superb and the skill shown is great. Craftsmanship is combined with quality engineering to achieve widely acclaimed and high-performance products.

German Engineering Is Leading The World

In 2004, Germany was the market leader in twenty-one out of thirty-one branches of the entire world’s engineering industry! At the time it represented a quarter of the entire world market.

Although most of the German engineering industry is dominated by small and medium sized businesses, that doesn’t at all hinder its success. In more than half of all exported items, computer and electronic expertise is included within the products manufactured.

You have to think about those wonderful German cars you purchase, like BMWs or Porsches. It’s not only the cars themselves that are engineering wonders, but over 25% of the value of the car is in the electronics and software these days. It makes for a good opportunity to work in the industry as the demand is high for excellent employees.

That is why Germany has become a very attractive place to come to train in computer and electrical engineering. You will find you can achieve a Bachelor’s degree, a Masters or PhD in a German university. Then you simply go out and apply for a job, and find one with ease. ![]()

Upon conducting some surveys, it was found that engineers in Germany don’t just work in research and development. This area is a good place to enter, but many engineers work in production and even management. Prospective employers are looking for accomplished graduates every day.

Germany has often been dubbed a land of thinkers. This is true within the German engineering field, too. Many accomplishments can be traced to individuals who originated from here. And the intellectual accomplishments of Germans have helped to shape the world.

Some examples of Germany’s great minds are Wilhelm Conrad Röntgen and the X-rays he discovered (and won the Nobel Prize in Physics for). Heinrich Rudolph’s work led to the telecommunications of modern day.

German Engineering And Its World Renowned Products

Then you can’t forget the incredible worldwide products stemming from top German companies. There’s the sleek and beautiful BMW, the luxurious Mercedes-Benz, and of course, Audi and Porsche. These companies are known and respected the world over.

Another global powerhouse is Siemens AG, producing in the energy and healthcare areas. They have been working at giving us high quality products for over 125 years. Hearing aids are just one of the most popular that they make. These hearing devices have been deemed the most technologically advanced and fit all.

And then you have Bosch, a corporation that is the largest manufacturer of power tools and accessories in the world. They have branches in other parts of the world as well, such as North America.

Krupp and BASF are other German leaders in engineering. Krupp makes coffee makers as well as espresso machines and blenders, toaster ovens and mixers. BASF manufactures chemicals used in fibers, resins and finishing compounds.

There’s no doubt that German engineering has been a top contributor to our industrial successes, and has helped us have the best in products for our ease and pleasure. We will see more to come in the future. Of that there’s no doubt.UNQUOTE.

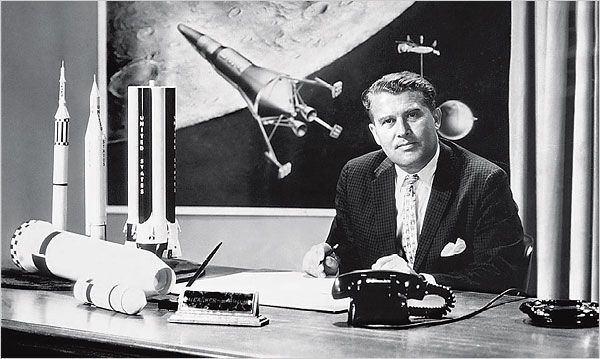

The archetypal German Engineering Genius,and one of my hero’s,Dr.Wernher Von Braun,who masterminded America’s NASA Space Programme,which included the highly successful Apollo moon landings:-

Dr.Wernher Von Braun with the enormous and impressive SATURN V SPACESHIP ROCKET ENGINES,for the APOLLO Programme:-

WIKIPEDIA:-

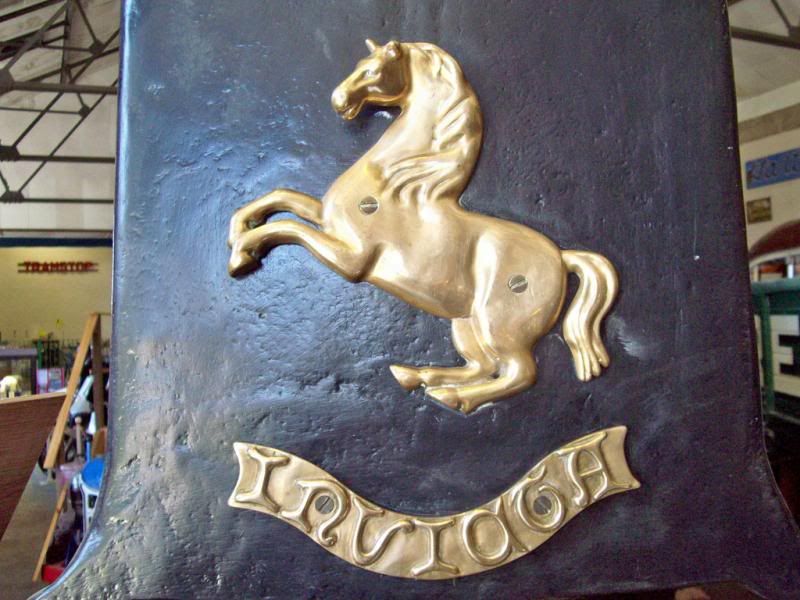

INVICTA (meaning undefeated or unconquered) was used in Roma invicta meaning “Unconquered Rome” and is the motto of the county of Kent, England ![]() :-

:-

What has INVICTA got to do with all of the above? ![]() Nothing!

Nothing! ![]()

![]() But it has got everything to do with the marque that is going to have the last say in my POST 22:-AVELING-BARFORD

But it has got everything to do with the marque that is going to have the last say in my POST 22:-AVELING-BARFORD ![]()

![]()

![]()

![]()

![]()

![]()

![]()

Aveling-Barford is yet another British Leyland company to miraculously survive Leyland’s iniquitous mis-management ![]() - from all reports,including me who had a chat with someone who used to work at Aveling-Barford’s Grantham factory,Leyland’s incompetent management wrecked the joint,i.e.company

- from all reports,including me who had a chat with someone who used to work at Aveling-Barford’s Grantham factory,Leyland’s incompetent management wrecked the joint,i.e.company ![]()

![]() After Leyland sold off what was left of Aveling-Barford to Wordsworth Holdings in 1988,who went into administration in 2010,the new owners re-built the Aveling-Barford

After Leyland sold off what was left of Aveling-Barford to Wordsworth Holdings in 1988,who went into administration in 2010,the new owners re-built the Aveling-Barford

marque and made a success out of the company ![]() Enter WIKIPEDIA again:-

Enter WIKIPEDIA again:-

In 2006 Singapore-based ST Kinetics bought the rights to the Aveling Barford RXD series articulated dumptrucks, which are now sold under the TRX Build brand.

In August 2007 Moxy Engineering of Norway announced plans to buy the intellectual property rights of the Barford rigid dump truck range.[2]

In or around 2010-2011 Moxy was purchased by the South Korean Doosan (formerly Daewoo).

AVELING AND PORTER - AVELING-BARFORD INVICTA PRANCING HORSE BADGE ,on the front of a Aveling and Porter or Aveling-Barford Steam Road Roller:-

AVELING-BARFORD started off as AVELING in 1858 and as AVELING & PORTER in 1862,and were based in

Rochester,Kent - hence the Aveling & Porter and Aveling-Barford INVICTA trademark and badge:-

AVELING AND PORTER - AVELING-BARFORD INVICTA PRANCING HORSE BADGE ,on the front of a Aveling and Porter or Aveling-Barford Steam Road Roller:-

AVELING AND PORTER LIMITED,ROCHESTER,KENT,ENGLAND.By Royal Letters Patent No.7898.Makers plate:-

The company,besides making traction engines,steam road rollers,etc,also made traction engine-based steam tramway engine railway locomotives,such as this example:-

AVELING AND PORTER COMPOUND 57,OR 72,OR 92 BHP 0-4-0WTG STEAM TRAMWAY ENGINE RAILWAY LOCOMOTIVE,No.8800,SIR VINCENT,1917.VICKERS,SHEFFIELD:-

Aveling & Porter made more steam road rollers than any other manufacturer in the world:-

AVELING AND PORTER F-CLASS COMPOUND 6 NHP 10-TON STEAM ROAD ROLLER,ENGINE No.11240,R0 641,STORTFORD ROLL,MAY 1925:-

AVELING AND PORTER KND COMPOUND 4 NHP 10-TON CONVERTIBLE TRACTION ENGINE,Engine No.7838,TA 2436,FRED,1912.Restored and once ownd by the late great FRED DIBNAH! ![]()

![]() :-

:-

AVELING AND PORTER LC8 CLASS COMPOUND 3-GEARS 8-NHP SHOWMANS STEAM ROAD LOCOMOTIVE,ENGINE No.4885,ME 6052,SAMSON,1901.CHARLES PRESLAND,AMUSEMENT CATERER:-

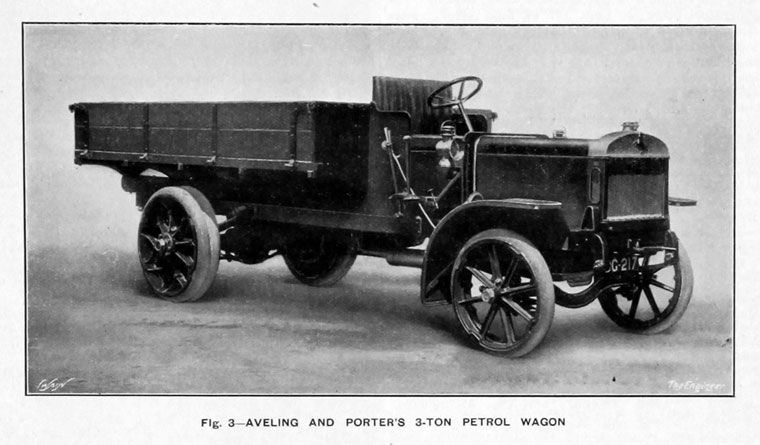

AVELING AND PORTER 3-TON,PETROL-ENGINED,DROPSIDE-BODIED,4x2 LORRY,Chassis No.7917,built 1912:-

AVELING-BARFORD.

Aveling & Porter became part of the Agricultural & General Engineers in 1919,but,due to the Great Depression and mis-management,it went bust in 1932,but most of the member companies survived,including Aveling & Porter that merged with Barford & Perkins to form AVELING-BARFORD in 1933.

Production was transferred from Rochester to Grantham in Lincolnshire,where the company continued

to make diesel and petrol road rollers (steam-powered ones were built until at least 1950),and later on graders,dump trucks,etc were made.

AVELING-BARFORD MARQUE INVICTA BADGE ON AB 690 6x4 DUMP TRUCK,NJT 344H:-

AVELING-BARFORD W CLASS SINGLE 6-NHP 10-TON STEAM ROAD ROLLER,ENGINE No.AH162,JXH 174,OMEGA.1948.

Ian and Wendy Beard:-

AVELING-BARFORD DCO12 DIESEL ROAD ROLLER:-

AVELING-BARFORD 6x6 MOTOR GRADER.Very interesting looking motor vehicle,two photographic views:-

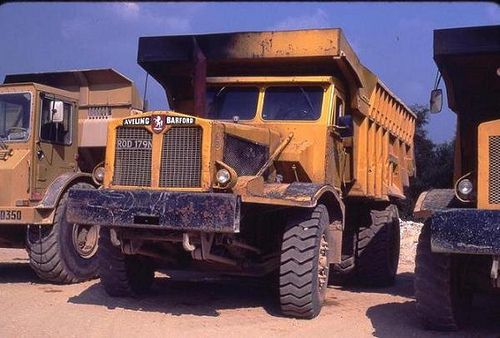

AVELING-BARFORD SN-35 4x2 DUMP TRUCK,ROD 179N:-

But that is not all to the AVELING-BARFORD story.British Leyland with it’s many marques was a virtual Who’s Who of a major part of the British Motor Industry,and was therefore a wonderful collection of British motor vehicle history and heritage some of which went right back in to the 19-Century and the days of steam traction for road vehicles ![]() This included,of course,Leyland Motors,Thornycroft and Aveling-Barford,who all built steam road vehicles

This included,of course,Leyland Motors,Thornycroft and Aveling-Barford,who all built steam road vehicles ![]()

AVELING-MARSHALL,FIELD-MARSHALL,ROAD-MARSHALL,TRACK-MARSHALL,CLAYTON & SHUTTLEWORTH,FOWLER,LEYLAND,MARSHALL,MARSHALL-FOWLER,NUFFIELD,STEYR,AVELING-BARFORD AND ALL THAT.

Part of British Leyland’s rich heritage,from 1975 to 1979,were three more illustrious marque names that went back to the days of steam traction for road vehicles,CLAYTON & SHUTTLEWORTH,FOWLER and MARSHALL.Clayton & Shuttleworth,of Lincoln,founded in 1842,was bought by Marshall,

of Gainsborough,in 1929.The Marshall company,founded in 1848,became part of the Thomas W.Ward

Group,of Sheffield,in 1936,which,in 1946,took over the Fowler company,of Leeds,which was founded

in 1850. The Fowler company was offically a subsidary of Marshall.

The Fowler company produced diesel engines,railway locomotives and bulldozers,while Marshall

produced Field-Marshall tractors,Track-Marshall tractors,Road-Marshall road rollers and so on.

From 1970 the products of both companies were sold under the MARSHALL-FOWLER marque name.

Marshall-Fowler was sold to British Leyland in 1975,was re-named AVELING-MARSHALL and continued

to make tracked tractor-bulldozers,tractors,road rollers,etc,while AVELING-BARFORD made dump trucks,motor graders,etc.

Since Aveling-Marshall was not a core-product company,and to raise money for the ailing Truck and Bus Division,Aveling-Marshall was sold to Lincolnshire farmer and businessman,Charles Nickerson,who in 1982 also bought the Leyland tractor division - formerly Nuffield in pre-British Leyland

days.The Aveling-Marshall name was replaced by the MARSHALL marque name for the tractors,and

Track-Marshall for the tracked tractors,but in 1985 the company went bust,the Marshall tractors

part was sold to Bentall Simplex,of Scunthorpe,who attempted to sell Steyr tractors under the Marshall marque from 1989,but this failed when Steyr started started selling Steyr-named tractors in the United Kingdom in 1991.

Track-Marshall was sold to the Flatters family in 1985,but was sold again,this time to the TWR = Tom Walkinshaw Racing Group (motorcar racing) in 1990,but,due to poor sales,production ceased in 1994.

And here is a representitive example of the wonderful heritage from one of the above companies ![]() :-

:-

FOWLER CRUSADER OIL-ENGINED,BOXVAN-BODIED,6x4 LORRY,Chassis No.19727,AKE 81,1932.Commercial Roadways Ltd London,Bromley,Kent:-

And another Aveling-Barford photograph:-

AVELING-BARFORD CENTAUR 35 AND 40 TONS PAYLOADS DUMP TRUCKS advertisement:-

VALKYRIE

newmercman:

Nice one RamoneThe bladder would be easy to inflate on a vehicle with a compressed air system! I thought you had an engineering background Geoffrey :ugeek:

Some engines (here’s a big clue [zb]) had terrible part load fuel consumption, so a simple few turns in the pump settings would give extra power, which wasn’t so much of a problem at full load, but the extra fuel was always being added and compounded the poor part load returns.

I wasn’t there, so it could be hyperbole, but we’re talking about factory drivers, they usually have a bit more about them than the screwdrivers you find in an RDC waiting room. Mind you there’s another side to that coin too. You were a factory driver if I remember correctly Geoffrey:grin:

![]()

I wasn’t referring to what the so called ‘bladder’ would or wouldn’t have been inflated with ( air ) in this case.I was referring to the method of control needed as to how and when the air was ‘automatically’ removed and put in it and why bother considering the obvious implications that the whole bs idea would be found out by anyone with any sense.Such as those who you’ve described ( as opposed to,as you say,the average RDC waiting room bs’er ) ![]()

![]()

![]() .

.

In addition to the simple idea of overfuelling the engine,just as I said,regardless of whatever way you want to dress it up,to create more performance than the thing actually has under it’s correct fuelling.Which,just as I’ve said,would be easily found out by anyone who could read a torque curve before they ever drove the thing and who knew the symptoms of an overfuelled engine when they saw them.As you’ve said I was a factory driver which is why,as I’ve said,any factory driver with any sense would know that any road tester with any sense would easily find out such an idea. ![]()

Therefore although admittedly just like you I wasn’t there,the fact that,as a factory driver,I’ve said that it sounds more like hyperbole ( bs ) to me and then having provided my reasons why,would have been understood by ‘any’ driver who’d been involved with serious testing of vehicles wether factory or not. ![]()

![]()

![]()

Which just leaves the ‘real’ question as to the ‘credentials’ of,who you seem to think were,the so called ‘factory drivers’ who went to all the trouble of somehow engineering a self inflating air bag,in a flawed attempt to make a fuel tank smaller ![]() ,to try ( and obviously inevitably failing to )

,to try ( and obviously inevitably failing to ) ![]() ) alter the fuel consumption figures of a standard engine,let alone one,that to add insult to injury,they’d also decided to over fuel in an attempt to make the thing go quicker than it should have done and who then thought that the road testers would be stupid enough not to notice the whole bs scam.

) alter the fuel consumption figures of a standard engine,let alone one,that to add insult to injury,they’d also decided to over fuel in an attempt to make the thing go quicker than it should have done and who then thought that the road testers would be stupid enough not to notice the whole bs scam. ![]()

That’s assuming the story was true of course. ![]()

![]()

![]()

![]()

newmercman:

Graham, the test fleet trucks are built using hand picked parts, all the loose parts will be hand picked to find the ones with the tightest tolerances. Once assembled they will be carefully run in on the bench before going in the chassis. Tyres are buffed down to get the lowest rolling resistance, extremely light weight oils are used, they all have the best aerodynamic options available, they’ll usually run direct top gearing, they’ll have the highest flow rate fuel filters and things that you and I probably wouldn’t think of in a hundred years.They may even have a bit of trickery like ported and polished manifolds and high flow exhausts, but that’s only my own thoughts. I would certainly do it all if I was running a press fleet, it’s not cheating, just making the best of what you’ve got.

Their drivers look after them very well. They put lots of miles on them to ensure everything is as it should be and monitor everything very closely.

That’s not a problem. Apart from the handbuilt engines, all the other procedures are available to the end user.

Attempting to get false readings is cheating. As I remember the vehicle in question was thrown off the test. The management denied all knowledge of wrong doing and the engineers were never let out in public again. How true that is nobody will ever know, but to make allegations that ABC manufacturers were trying to cheat is inviting a lawsuit that would put a magazine out of business, even small manufacturers like Dennison would have more financial clout (& better lawyers) than a magazine would. Goliath would always give David a beating in a case like that.

Just to put another side to that scenario,at least in my experience,all vehicles used for publicity purposed were all running with new standard components and all were customer vehicles with individual testing being a requirement to meet the stated specifications before being handed over to the customer.There was no such thing as a factory test or publicity fleet.Not surprising being that lives depended on how fast the thing got to the scene of an incident. ![]()

![]()

Airport fire engines are slightly diffrent to building tractor units that can easily be sold on

newmercman:

Graham, the test fleet trucks are built using hand picked parts, all the loose parts will be hand picked to find the ones with the tightest tolerances. Once assembled they will be carefully run in on the bench before going in the chassis. Tyres are buffed down to get the lowest rolling resistance, extremely light weight oils are used, they all have the best aerodynamic options available, they’ll usually run direct top gearing, they’ll have the highest flow rate fuel filters and things that you and I probably wouldn’t think of in a hundred years.They may even have a bit of trickery like ported and polished manifolds and high flow exhausts, but that’s only my own thoughts. I would certainly do it all if I was running a press fleet, it’s not cheating, just making the best of what you’ve got.

Their drivers look after them very well. They put lots of miles on them to ensure everything is as it should be and monitor everything very closely.

That’s not a problem. Apart from the handbuilt engines, all the other procedures are available to the end user.

Attempting to get false readings is cheating. As I remember the vehicle in question was thrown off the test. The management denied all knowledge of wrong doing and the engineers were never let out in public again. How true that is nobody will ever know, but to make allegations that ABC manufacturers were trying to cheat is inviting a lawsuit that would put a magazine out of business, even small manufacturers like Dennison would have more financial clout (& better lawyers) than a magazine would. Goliath would always give David a beating in a case like that.

This isnt a smart ■■■ response but ,and i dont doubt it in any way, if all the vehicles on test were "fettled" wouldnt they cancel each other out or am i missing the point?

VALKYRIE:

Carryfast wrote:-

The Germans in general have always been just average engineers compared to the Brits but somehow managed to invest loads more money in it’s industries especially in the post war years and it’s that investment which has always been reflected in it’s products.UNQUOTE.VALKYRIE replies:-

Please correct me if I am wrong,but you seem to be a bit paranoid in regard to Leyland’s former

Director of Engineering,Dr-Ing Alfred Mueller,who was an excellent engineer,contibuted to Leyland

engineering in a positive way and was the mastermind of the radical rear-engined Leyland Atlantean Double Decker Bus and Motorcoach which was pace-setting and highly successful.

Imagine the year is 1963 (actually it’s a 2005 historic motor vehicle rally photograph),and here

are two conventional front - engined Leylands and a unconventional rear - engined Leyland Atlantean…but some time in the not too distant future,rear-engined motorcoaches and buses would become conventional:-

LEYLAND ATLANTEAN PDR1/1/WEYMANN CH59F DOUBLE DECKER MOTORCOACH,RRN 428,Ribble 1279,1962,left.LEYLAND TITAN PD2/3/EAST LANCS FCL49RD MOTORCOACH,DCK 219,Ribble 1248,1951,right,and a Leyland Tiger PS1 or PS2 with the beautful archetypal Leyland appearance in the middle

:-

As I stated in Part 13,page 20,in this thread:-

THE GERMANS ARE VERY CLEVER ENGINEERS.I have always admired the Germans in regard to their engineering know-how,innovation,invention

and perfectionism,the Germans are very clever,precise and intelligent engineersThey have

excelled in radio communications engineering,motor vehicle engineering,electrical engineering,

aerospace engineering,and so onAnd do not forget that a great German engineer-scientist,

Dr.Wernher Von Braun,who is one of my HEROES,masterminded America’s highly successful space

programme,that included the Apollo men on the moon missionsHe is credited as being the “Father of Rocket Science”

And the above objective facts reinforced with following statement from this linked website

:-

mygermancity.com/german-engineering

German Engineering Is A Leading Engine In Our World

German engineering seems to remain always in the champion division of the entire industry. As an example, this successful country maintains their great reputation as the top exporter of machinery and industrial equipment.

The quality is always superb and the skill shown is great. Craftsmanship is combined with quality engineering to achieve widely acclaimed and high-performance products.

German Engineering Is Leading The World

In 2004, Germany was the market leader in twenty-one out of thirty-one branches of the entire world’s engineering industry! At the time it represented a quarter of the entire world market.

Although most of the German engineering industry is dominated by small and medium sized businesses, that doesn’t at all hinder its success. In more than half of all exported items, computer and electronic expertise is included within the products manufactured.

You have to think about those wonderful German cars you purchase, like BMWs or Porsches. It’s not only the cars themselves that are engineering wonders, but over 25% of the value of the car is in the electronics and software these days. It makes for a good opportunity to work in the industry as the demand is high for excellent employees.

That is why Germany has become a very attractive place to come to train in computer and electrical engineering. You will find you can achieve a Bachelor’s degree, a Masters or PhD in a German university. Then you simply go out and apply for a job, and find one with ease.

Upon conducting some surveys, it was found that engineers in Germany don’t just work in research and development. This area is a good place to enter, but many engineers work in production and even management. Prospective employers are looking for accomplished graduates every day.

Germany has often been dubbed a land of thinkers. This is true within the German engineering field, too. Many accomplishments can be traced to individuals who originated from here. And the intellectual accomplishments of Germans have helped to shape the world.

Some examples of Germany’s great minds are Wilhelm Conrad Röntgen and the X-rays he discovered (and won the Nobel Prize in Physics for). Heinrich Rudolph’s work led to the telecommunications of modern day.

German Engineering And Its World Renowned Products

Then you can’t forget the incredible worldwide products stemming from top German companies. There’s the sleek and beautiful BMW, the luxurious Mercedes-Benz, and of course, Audi and Porsche. These companies are known and respected the world over.

Another global powerhouse is Siemens AG, producing in the energy and healthcare areas. They have been working at giving us high quality products for over 125 years. Hearing aids are just one of the most popular that they make. These hearing devices have been deemed the most technologically advanced and fit all.

And then you have Bosch, a corporation that is the largest manufacturer of power tools and accessories in the world. They have branches in other parts of the world as well, such as North America.

Krupp and BASF are other German leaders in engineering. Krupp makes coffee makers as well as espresso machines and blenders, toaster ovens and mixers. BASF manufactures chemicals used in fibers, resins and finishing compounds.

There’s no doubt that German engineering has been a top contributor to our industrial successes, and has helped us have the best in products for our ease and pleasure. We will see more to come in the future. Of that there’s no doubt.UNQUOTE.

The archetypal German Engineering Genius,and one of my hero’s,Dr.Wernher Von Braun,who masterminded America’s NASA Space Programme,which included the highly successful Apollo moon landings:-

Dr.Wernher Von Braun with the enormous and impressive SATURN V SPACESHIP ROCKET ENGINES,for the APOLLO Programme:-

VALKYRIE_

Firstly I don’t see anything there which would disprove my comments that any superiority which German engineering has ever had over British engineering has all just been a reflection of the amount of money which was put into Germany’s industries and ideas over the years v their British competitors.The Appollo programme v the British especially proving that fact.

While I could probably put a list a lot longer than that concerning British superiority in everything from ship building and electronics to aerospace engineering over the years.As for cars just the two ideas of disc brakes used on the Jaguars at Le Mans v the German answer in the form of an air brake on the SLR to save it’s drum brakes form fading ![]()

![]() or swing axle IRS on it’s sports and saloon models v Jaguar IRS says everything.Let alone aircraft like the Griffon Spit v the Focke Wulf 190 or British superiority in radar technology which helped to defeat Hitler’s submarine menace etc etc etc.

or swing axle IRS on it’s sports and saloon models v Jaguar IRS says everything.Let alone aircraft like the Griffon Spit v the Focke Wulf 190 or British superiority in radar technology which helped to defeat Hitler’s submarine menace etc etc etc.

While Mueller’s contribution to Leyland seems to have been contributing to the ideas of the 500 and L60 engines.As I’ve said the former of those seeming to be a possible example of industrial espionage.While the latter was an example of retrograde German aerospace technology used in the Chieftain v the superior Merlin based Meteor in the Comet/Centurion tanks. ![]()

[quote=“VALKYRIE”

Ramone wrote » Sun May 26, 2013 3:29 pm:-

CF, how can you say that the 3VTG cab would have been more successful than the Marathon when you know absolutely nothing about it ,all you know is what you`ve seen on here a few photos of a prototype that looked like a yank mounted on an AEC chassis for testing.You dont know what the ride was like ,the space inside, the visibility ,you know absolutely nothing whatsoever ,like most of your postings on here its either hindsight with your usual quote of history shows ,or just disagreement for the sake of it .I still cant quite make out why you compare the Marathon with the much higher powered F12 when it was the F10 which had a very similar output,maybe you wouldnt like the results of a test match between those 2.UNQUOTE.

VALKYRIE replies:- This is a refresher on what I wrote,and I will have to re-quote myself (it saves time and effort in re-writing it all again,anyway!):-

"Best Ergomatic Cabbed-Lorry Model? PART 4.Page 10.TRUCKNETUK

I’ll quote myself first:-

AEC SUPER MANDATOR V8 3VTG High Tower 6x4 PROTOTYPE CONCEPT PROJECT LORRY.

As I said in my last post,the wise AEC 3VTG Concept Project Lorry was the wise and inspired idea of the boss of AEC,Dr.Albert D.Fogg,who obviously wanted to copy Volvo with it’s refined American-style F88-F89 lorry models,and produce a refined American-style AEC heavy lorry range ![]() And in the words of the great Barry Norman:“And why not”…

And in the words of the great Barry Norman:“And why not”… ![]() And why not indeed,because other lorry manufacturers were doing the same thing

And why not indeed,because other lorry manufacturers were doing the same thing ![]()

The interior of the AEC 3VTG cab was well-appointed,with Bostrom Viking seats,a very comprehensive instrument panel and good cross cab access. The lorry’s engine bay allowed more air to circulate around the engine than with the Ergomatic Cab,and it’s AEC 801 Series V8 engine had a much larger header tank,radiator and cooling fan than the AEC Mandator V8.

Albert Fogg wanted to produce a better cab than the Ergomatic,and he was well on the way in doing this with his AEC 3VTG Lorry ![]() He realised that the Ergomatic was not big enough,it produced cooling problems for the engines,especially in the tropics,it had design flaws and,according to Albert Fogg,it was not suitable for long distance motorway journeys. So entered the AEC 3VTG Project-Concept-Prototype Heavy Lorry for all of the above reasons that I’ve listed

He realised that the Ergomatic was not big enough,it produced cooling problems for the engines,especially in the tropics,it had design flaws and,according to Albert Fogg,it was not suitable for long distance motorway journeys. So entered the AEC 3VTG Project-Concept-Prototype Heavy Lorry for all of the above reasons that I’ve listed ![]()

But,as I’ve already stated,Leyland mismanagement very misguidedly scrapped the AEC 3VTG Programme ![]() …and by doing so,it was yet another long,long,sharp,sharp nail in the unholy coffin of the British Leyland Motor Corporation!

…and by doing so,it was yet another long,long,sharp,sharp nail in the unholy coffin of the British Leyland Motor Corporation! ![]()

![]()

AEC SUPER MANDATOR V8 3VTG6RGAE 090 Mk1 High Tower Project-Concept-Prototype 6x4 Tractive Unit Specifications:-

Cab: Motor Panels Tilt Cab,modified.

Engine: AEC 801-Series-AVM8/801,13.1-Litre,V8 Diesel Engine,producing 272 BHP @ 2600 rpm,638 lbs ft of torque @ 1400 rpm.

Gearbox:Leyland-Self Changing Gears -SCG Pneumocyclic 10-forward speed Splitter Semi-Automatic Gearbox.

Rear driving axles: Leyland Group Hub Reduction Drive Axles.

Year:1968.

Not only was Dr.Albert D.Fogg the General Manager of AEC Ltd,he was a member of the board of the British Leyland Motor Corporation,Deputy Managing Director of this corporation and Director of Engineering of British Leyland. So his above various positions within British Leyland allowed him a substantial amount of influence within British Leyland and at AEC,thus,the AEC 3VTG being Albert Fogg’s pet project,he probably had every intention in eventually turning it in to a production lorry to take on the likes of the Volvo F88-F89,Scania LB110,etc ![]()

But of course,British Leyland mismanagement very misguidedly scrapped the 3VTG project ![]() ,which proved to be fatal for British Leyland in the long - as did the scrapping of the AEC marque!!!

,which proved to be fatal for British Leyland in the long - as did the scrapping of the AEC marque!!! ![]()

![]()

![]() .

.

According to Pat Kennett,development work started on the Leyland Marathon in circa 1971,and this lorry turned out to be a compromise because of the limited financial budget allotted for it’s development ![]() -

-

the AEC 3VTG would probably have been better and more successful than the Leyland-AEC Marathon ![]()

The Marathon was introduced in 1973. But instead of using the money for the Marathon project, AEC-Leyland might have saved some of this money getting rid of the V8 engine’s problems,fully developing the Motor Panels 3VTG cab and getting the AEC 3VTG heavy lorry range in to production,probably in 1972 ![]() It would not have been the compromise that the Marathon was."UNQUOTE.

It would not have been the compromise that the Marathon was."UNQUOTE.

If the AEC Super Mandator V8 3VTG High Tower PROTOTYPE was rough-riding,I’m sure that the ride would have been greatly improved for the production version,and,as I said in my Post 13,page 20:-

VALKYRIE:-"Albert Fogg’s AEC Super Mandator V8 3VTG High Tower 6x4 Tractive Unit,which looked like a Peterbilt High Tower COE,and was also in the same idiom as an Australian Atkinson High Tower COE,was designed for better engine cooling,better driver comfort and high power for long distance heavy duty freight trunking,and would have been for sale in British,European,Australian,New Zealand and other markets - as I said my PART 4:AEC and Albert Fogg were wisely doing a Volvo F88-F89! ![]()

![]() "

"

Since this was a prototype,and not a production example,it is fair to say that a production

version would have been moderately re-styled to look more English-European than American,while

also appealing to the Australian,New Zealand,etc,markets,who buy a lot of American heavy motor

trucks-lorries ![]() UNQUOTE.

UNQUOTE.

Val, my point was that you cant compare a production vehicle with a prototype that never went into production.It may very well have been a great success but then again it might not.It looked to me in some ways a backward step with the small split windscreen and side windows.On the other hand it may have been just what hauliers were looking for ,but we will never know .Maybe it was a project AEC had undertaken to show what they were capable of and Leyland took exception to it,or maybe there were serious design faults,but i suspect what you have said is much nearer the truth that finances were the problem.It certainly looked impressive , i have searched my house top to bottom but cannot find the Aec gazette i had with a test drivers story of his time behind the wheel of the Marathon prototype which had the very same 3VTG cab but Wwith the TL12 instead of the V8.He told tales of great performance whilst he drove daily along the M4 west and then back to Southall and im almost certain he said it was running at 40 tons.Another thing i vaguely remember was that the cab was filled with test equipment and was a mock up with no proper dashboard ,the story was covered over a couple of editions of the gazette .Maybe Graham might have the copies

BTW don’t forget the “Marshall Plan” that pumped millions of dollars into Germany after WW 2 and rebuilt industry, the allies won the war Germany won the peace, the economy went from strength to strength thanks to that(was in Berlin a while back the technology museum is well worth a visit)

At the moment im reading an autobiography of lenoard lord the austin then bmc boss. One of tbe veiws mentioned about the marshall plan was the labour government of 1945 had to use the money Britain got which was more than germany got to bring in there promises to the british people which was basicaly the welfare state as other than this the country was skint.

Totaly unrelated i know

gingerfold:

I’m sure that all vehicles submitted for magazine testing are specially prepared and not picked off the production line at random. When I was a teenager I was on a trip with Ray Holden in the lorry and we were in south London. Ray had been a flight engineer in Bomber Command during WW2 and whilst in London we called to see one of his former RAF comrades, also a former flight engineer, he worked at a special garage preparing Ford cars for magazine testing. It was an interesting and enlightening visit.

Evening all, well tonight I`m afraid that this old boy is just too cream crackered to post a detailed reply, based upon my own personal experiences with road tests. Its been a 16hour day, and at well over three score and ten, I expect I should be tired!!

Mark, Graham, buffed tyres, thin oils, selected components…changed a lot from my days!

Thinking about Pat, when he was technical editor at Motor Transport, he did a test on the first Saviem that you had in the UK, an SM32 240. The then importer, Nickerson, (and what delightful people they were indeed…totally unsuited to the rough and tumble of the declining UK transport industry)! Well, Pat asked Nickerson for a vehicle to test…they gave him one of their own fleet day cab 32 240s coupled to a Task tandem tipper full of aggregate! Now Pat had broken his ankle , and was in plaster at the time, yet he conducted that test, (and found the Saviem comfortable to drive, despite his impairment), how we both laughed about that test…but it was an “honest” one.

The 79 Eurotest, the TR305, she was straight from our big European “Economy run”, not modded in any way, she was just the one available, and didnt she do well. But the real heroes were the Spaniards with their Baerriros, poor sods had been trampled by Chrysler, then Talbot ownership, now they had become “our” Spanish off shoot, boy, did they have their posteriors in their hands!!! But that emulsion painted, (I kid you not), KP went like a ding bat. Yes the 141 did not seem normal, but Pat dealt with that in his true style…he had a portable typewriter, and some of the things written on that machine…well it was a wonder that they did not melt it down!!!

In the UK, from “your” national titles you got good objective reporting, Gibb Grace, AJP (Tony) Wilding, Graham, (The Mad Monk), Montgomery, ex Dodge, Jon Barras, the Isle of Wights, “Cruncher” Mike Cunningham , and of course Pat, all to a man good objective engineering based journalists, all with “real” industry experience.

That Pat met Andrew Frankl, (complete with a maniquin on his shoulder), at Kelvin Hall, was one of those fortunate meetings that we all benefited from…the Force Four Truck Magazine, and Pats revolutionary idea of the Eurotest, and the European Truck of the Year competition. The former, becoming, with Trucks European partners, the benchmark testing procedure across Europe, and the latter, exposing UK products to a wider market. A market that some manufacturers were able to enjoy.

Post `78, the Renault Vehicules Industriels emphasis was towards as much Press and media exposure as possible for our mainstream products, and for maxi-code, that is 38tonnes, then it was the big TRs. But the test vehicles were well run in, but nothing else pertained, (was it an age of pre at all costs concious image)? But one main difference to the UK press tests, Les Officials des Transporters, Camion Magazine, France Routes, La Vie des Transports, (under the superb Roger Roy, a very similar character, in his search to find the best in each test, to Pat). Les Poid Lourd, Hollands Transporterama, all ran top weight vehicles with Savoyard, or Tilt type trailers. Far more representative, in performance terms, of what the operator should receive/expect in his own operation, than a weighted low hight platform trailer.

That in later years the test procedures were abused, or deteriorated saddens, but not surprises me. The industry changed, and changes still, c`est la vie.

Back to the thread, what T45 was operated, and to some success in the good old USA, …and why did that self same vehicle end up in Stoke on Trent??

Cheerio for now, bed calls!!!

kr79:

At the moment im reading an autobiography of lenoard lord the austin then bmc boss. One of tbe veiws mentioned about the marshall plan was the labour government of 1945 had to use the money Britain got which was more than germany got to bring in there promises to the british people which was basicaly the welfare state as other than this the country was skint.

Totaly unrelated i know

The way I heard the story from those who were there at the time.Much of the small amount of money that the country had left at the end of the war ended up going into rebuilding Germany and it’s industries,such as Volkswagen for example,regardless of how the British government have tried to re write history since to show that Germany won the peace because of it’s so called ‘better’ ‘less militant’ workers.

If I’ve heard it right Britain was under rationing long after the end of the war while the Germans weren’t and were actually recieving food and fuel aid from us such as in the Berlin airlift while our own people went hungry and cold.All to make sure that the Germans stayed on side at the start of the cold war. ![]()

Did you know people who were in senior positions of government after ww2 then

Hey,

About testing lorries, they are always optimized even an alternator which takes less power can add and so on. In my view tests say nothing,in use it says lots more as told part loads emty runs and so on. Let’s say our 141’s were better on fuel with heavy loads as it was better to use the 111’s for light weights.

About germany,it is built up after WW II with American money it never had can rebuild his country alone.I will never blame them they are very clever but have a real look. It was the country at the wall to the east. Look what work they have given Germany by building lots miltary basis and so on and on Our belgian factories built works there for the women of the belgian soldiers,and in each work were Germans at work too and all by all everything was good for feeding the German treasury.So they lived there and bought their livilihood that’s only something they did. But it were and are still very clever men they developed and developed. And they are very chauvinists and when all work together you can reach very much as working alone of course there was competition too. You can always buy at them but selling to them you have to be very very strong. But in lots of branches the japs or other have taken over their business too.

And in lorries only two have survived but are real world players with quality. I think Leyland bought up so many so it must had been possible to survive by using the best engineers and best parts of the bought marques. Look MAN has bought Büssing and became so a very good quality builder.Merc bought Henschel and learnt lots from their engineers. This two had a big money back grounds and bought and used the competitions know-how.

Goverment subsidised and owned companies are never good. So was it with Renault too now in Volvo hands maybe Saviem can tell more about that.

Cheers Eric,

Saviem, re T45 in the US when I get home(to main computor) will post some information on a proposed deal with an American entrepreneur to import them suitably modified for the US market