Hello all, I’ve joined the forum as I’m after some help with a trailer I’ve bought and am modifying to use as a farm trailer towed by tractors. It’s a 45’ stepframe 2002 model cartwright which I’ve cut the neck off, leaving me with about 32’ which I am welding a drawbar on to. As not all tractors have air, I’m having to change the brake chambers from regular spring brake chambers to service chambers (also have a hydraulic ram for use with tractors without air). This means I can do away with the park and shunt valves and basically simplify the whole system. Also has ABS (I think) so can remove all of that. I’m having trouble getting my head around what parts I can get rid of and how to simplify it (also getting rid of 1 of the 3 tanks). The air tanks will be filled by some sort of simple compressor for the purposes of keeping the suspension up, when not hooked up to a tractor with air. What I need is for someone to explain to me in very basic terms, what I need, in order, from couplings on the front of the trailer to where it connects to the chambers and air springs - ie what valves etc. I’ve had a look for diagrams on the internet but can’t find anything that matches what I want to do as they all have spring brake chambers and ABS modules etc. Hopefully someone can understand what I’m getting at and help me!

Thanks in advance - James

Try here

Or here http://bit.ly/1Ggo2Kp

As for the ABS, forget it as you wont have an ABS lamp in the tractor to tell you it isn’t working ![]()

And you will need to fit an air dryer after the compressor on the trailer.

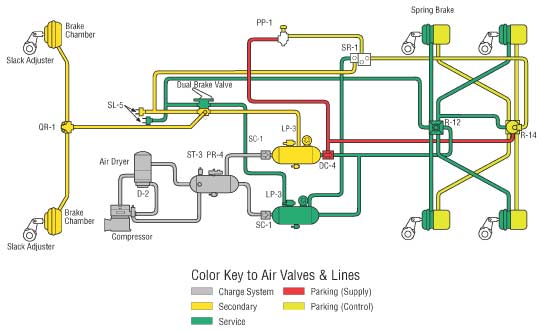

Thanks for that, am I best leaving the ABS module in place then? I found a few diagrams like that but struggling to find one with a key that describes all of the valves etc, just struggling to get my head around what my finished system will look like! Doesn’t help my confusion with all the air lines having being painted black! Is the green tank in the diagram the one connected to the red air line on the tractor?

Try on thefarmingforum.co.uk/index.php or you could look up A M Dykes and email them as they have a low loader for their tracked plant that they pull with a John Deere.

I don’t know what you intend to carry on this trailer, but what immediately springs to mind is that if converted to a fixed drawbar rather than a dolly under the pin, then it is going to impose a lot of weight on the tractor. You will need to do some calculations. If you delete the spring brake chambers and the park brake button then you are going to need a manual parking brake. You will also need to ensure that a loss of air in the air suspension system does not deplete air from the braking system. You need proper professional advice from a trailer manufacturer.

Purely out of curiosity what are you planning to use this trailer for as it’s not a route I would have gone down. Interesting project though.

Trailer will mainly be used for straw, 9-12 tons of it, and possibly an excavator in the future if I can work out a neat design for some ramps. There won’t be much nose weight on the trailer, the centre of the trailer (at it’s new length) is between the front and middle axle. Ideally wants a bit more weight on the drawbar than it would have with an even load such as straw. Not sure what to do about a parking brake, agricultural trailers tend to have a cable that pulls on the actuating lever but as this trailer is on disc brakes, can’t do that. Can’t say I’ve ever used a parking brake though, trailers aren’t left loaded and when unhooked, the friction of the drawbar on the ground is enough to stop it moving. It has been done a few times before, but every one I’ve seen do it has left the air system as it is, which I can’t do. I’m now thinking the best way to research the system I need is to go to a dealership that sells trailers with air + hydraulic brakes, and just have a nosey at them and draw a diagram off that.

We had 2 x Smyth 14t silage trailers with air over hydraulic brake systems and Portequip do a very good 32’ flatbed.

Biggest problem with flatbed trailers is getting them through gateways to/from narrow roads and tracks. We’d originally thought about a 28’ but went for 25’ from experience and that’s still too tight for some places ![]()

To be honest I think you will struggle with this. Pretty much anything is doable but that doesn’t necessarily mean it makes sense.

Obviously, this isn’t what you want but by far the best option is to fit the tow vehicle with the necessary kit which means you could keep everything, including the ABS relatively straighforwardly.

Ignoring that though I don’t see removing spring park brake as an issue. New chambers were unnecessary though you could have just wound the springs off and once that was done it would be possible to just cut that part of the chamber off if you were feeling brave - you need to know what goes on inside before doing this as the springs are very powerful and dangerous. If you’re putting service chambers on you will potentially need to be careful with compatibility and ensuring push rod length and throw matches.

The lack of spring brakes are only an issue when parked and no air. You are still going to need a two line system and an emergency relay valve so it would still lock up in he event of a breakaway.

A low farm trailer fitted with aged disc brakes does not sound the best idea to me, discs are ok on axles that are being used most of the time, if the thing stands for a fair time you could well end up with the callipers going tight on the sliders, add to that a rusty disc then you’ve soon got a disc that’s running red hot fitted with small wheels, not the best idea with a load of straw on board!

I have done a fair amount of straw in my time with step frame trailers though none have ever been fitted with disc brakes, the other thing is that the brake chambers are often fitted in a position that’s not suited to off road driving!

The stumbling block is going to be how to work the fail safe emergency line if, as indicated, it is the intention to pull the trailer with tractors that do not have an air system. The more information which comes to light the more this sounds like a disaster waiting to happen. I’m guessing that this trailer is going to weigh about 5 tonnes when finished, add 12 t of straw etc or 13/14t for a 360 machine and that’s a lot of weight for a DIY braking system. I too cannot see a disc brake system working efficiently in the environment proposed.

The sooner road-going farm tractors and trailers become liable for MOT the better. The best option would be to obtain a modern purpose built farm trailer which will have been designed for the job.

Think you need advice from Dave the Renegade, he is full of help on agricultural matters.

cav551:

The stumbling block is going to be how to work the fail safe emergency line if, as indicated, it is the intention to pull the trailer with tractors that do not have an air system. The more information which comes to light the more this sounds like a disaster waiting to happen. I’m guessing that this trailer is going to weigh about 5 tonnes when finished, add 12 t of straw etc or 13/14t for a 360 machine and that’s a lot of weight for a DIY braking system. I too cannot see a disc brake system working efficiently in the environment proposed.The sooner road-going farm tractors and trailers become liable for MOT the better. The best option would be to obtain a modern purpose built farm trailer which will have been designed for the job.

It sounds like as he’s cut the neck off it’s going to have to be seen to conclusion so discs will just have to be lived with.

I think some sort of of load sensing function is going to have to be retained or it will be leaving it’s tyres all over the tarmac if unladen or light.

It worries me the trailer could be EBS at that age in which case it will use electrical sensors for load sensing and ride height so they will need to be replaced with traditional mechanical/pneumatic valves.

On the air suspension side it sounds like he wants to supply it if the tow vehicle has no air supply. Presumably a vehicle electric powered compressor (I’m not optimistic for the long term well being of this but it’s ok I suppose). If the suspension is isolated from the brake air then I don’t see the need for the drier someone else has mentioned. I would put plenty of work into making the system good and airtight.

In summary, on the braking side.

Leave standard connections on trailer, and the filters in the lines, also the emergency relay valve, then you need some sort of load sensing modulation on the yellow signal line prior to operating another basic relay valve that will send air from the tanks to the chambers. On the vehicle side it’s going to need some sort of proportioning function to allow make some effort at progressive braking.

This company sells kits aimed at the farm market but I would think a lot could be sourced cheaper separately.

I think ‘disaster waiting to happen’ is a little bit pessimistic! Although I take on board the bits about disc brakes being unsuitable, to be honest when I bought it I didn’t even imagine that it would have discs rather than drums! It’s a bit late now though, it’s going to have to work, calipers will be stripped and sliders copper greased to minimise the risk of problems. The trailer will be used regularly throughout the year so that should help keep things working. I don’t think I’m going to build in a fail safe unless I can work out a way of doing it that will work with air-less tractors. Hydraulic brake systems have no fail safe and they’re the accepted standard.

I am aware of the dangers with the springs in brake chambers, but thanks for mentioning it anyway. The chambers will be getting replaced, for an air over oil type. The chambers are pretty much on the top of the axle, so should be reasonably safe from damage. The chambers that I’m buying have a throw of 3mm less than the ones currently fitted - I assume that would be within tolerances (considering the weight will be less than the trailer was designed for)?

Erentek do a single mechanical load sensing valve that deals with both the hydraulic and air braking systems in one, think I’ll be buying one of those, but not sure how that will work with the air suspension if it is self-leveling as I assume? Not sure whether to go for an electric compressor, PTO compressor or hydraulic compressor, all the options look relatively cheap and suitable. Not worried about that for now though, that can come at a later date. Is the suspension tank isolated from the brake tanks or not?

As for buying a ready made, purpose built trailer, easy enough to say that but this trailer will have cost well under £2000 when it’s done and I’ll have a trailer exactly the way I want it. Plus I like a challenging project and like the satisfaction of having completed job well done. Looking at about £9000 for a similar trailer with the features I want, so certainly worth the saving.

Thanks everyone for the advice, certainly helping ![]()

If it doesn’t have a fail safe system so that the brakes apply automatically if the tractor and trailer part company then it has no place on the road.

There were pictures on here a few months ago showing what happened when a farm trailer broke free, the people in the following vehicles were very very lucky.

cav551:

If it doesn’t have a fail safe system so that the brakes apply automatically if the tractor and trailer part company then it has no place on the road.There were pictures on here a few months ago showing what happened when a farm trailer broke free, the people in the following vehicles were very very lucky.

I agree that it’s a good idea to have one fitted but I don’t know any farmer that has a trailer with a fail safe and it never seems to come up as an issue. Hydraulic systems can be very dangerous if a pipe bursts - braking will pump all of the fluid out in a matter of seconds, leaving you with no steering and no trailer brakes, and I imagine the tractor brakes would overheat very rapidly (again, a few seconds) with no oil to cool them, that really would be a disaster scenario. If someone can explain how I can have a fail safe that would work in this set up, then I would like to have one. Is ‘emergency relay valve’ the component I need? Or is that what’s used with spring brake chambers? The whole design and purpose of a fail safe device - ie applies brakes when pipes disconnected - makes it very difficult to incorporate to an air/hydraulic system as only one braking system is connected at any time, the other system uncoupled and fail safe device active.

You can get hydraulic valves that are operated by a handle you could incorporate a ratchet and a breakaway cable. You will have a fail safe on air already.

Are you sure the air over hydraulic cylinder is compatible, I don’t think 3mm of throw will matter but apart from ROR axles there are only a handful of calipers that are compatible with a yoke and clevis?

With the spring park brake removed some of your potential trouble with discs are removed. I would say there is an industry tendency to overstate the downsides with discs.

There are check valves to ensure leaks from the suspension side don’t eat the braking air. Self-levelling and load sensing are two different functions although load sensing will use bag pressure . Load sensing for hydraulic will use some mechanical spring ordinarily but would presume on a combined valve it’s going to have to use bag pressure as well.

Own Account Driver:

You can get hydraulic valves that are operated by a handle you could incorporate a ratchet and a breakaway cable. You will have a fail safe on air already.Are you sure the air over hydraulic cylinder is compatible, I don’t think 3mm of throw will matter but apart from ROR axles there are only a handful of calipers that are compatible with a yoke and clevis?

With the spring park brake removed some of your potential trouble with discs are removed. I would say there is an industry tendency to overstate the downsides with discs.

There are check valves to ensure leaks from the suspension side don’t eat the braking air. Self-levelling and load sensing are two different functions although load sensing will use bag pressure . Load sensing for hydraulic will use some mechanical spring ordinarily but would presume on a combined valve it’s going to have to use bag pressure as well.

I like the idea of a fail safe on the hydraulic side using a breakaway cable, something I’m head scratching over at the moment. With the fail safe on the air system, will that cause the brakes to be on all the time there is air in the tank and no air lines are connected? I suppose shunt valve would be used with this in case there is air in the tank when I want to use it with an air-less tractor.

Am I sure the air over oil chambers are compatible? ‘No’ would be the answer to that, I am going to have to fabricate some brackets and remove the clevis/pin, will probably turn the end of the shaft on the lathe to give a ‘ball’ sort of end. I know they will not be a simple bolt on job, but I will find a solution.

Sorry, I didn’t mean to confuse the terms self leveling and load sensing, what I was getting at was will load sensing brake valves work with self leveling suspension? Every load sensing brake valve I’ve come across, for air or hydraulic on agricultural trailers, adjusts braking pressure according to distance between chassis and axle (smaller distance = more weight on trailer = more braking pressure) but if the suspension keeps level regardless of load, then it’s not going to do it’s job very well ![]() I didn’t realise HGV trailers used spring air pressure to work the load sensing valve, mine could be electronic sensors though as you say.

I didn’t realise HGV trailers used spring air pressure to work the load sensing valve, mine could be electronic sensors though as you say.

You might be able to allow the air to exhaust when you drop the red line, put in a hand valve to dump it or yes shunt will work - that just effectively tricks the emergency relay valve into thinking the red line is attached.

If you are fabricating brackets they will have to be very substantial even the factory mounts flex alarmingly under full pressure. They might be ok to start with but you can easily find welds or even the metal cracks further down the line.

To be honest if you’d gone for drums chances are the air over hydraulic chambers would have been a straight bolt on too late now though, obviously.

I did follow on the load sensing. I am sure it must use bag pressure for the air and hydraulic combined valve as yes with self-levelling the suspension will never move.

I understand the project element but this really does not make sense, to my mind, you would be much better investing the time and money in fitting all potential tow vehicles with an air capability which would mean they could then tow any standard drawbar or artic trailer with a dolly rather than the other way round.

Own Account Driver:

You might be able to allow the air to exhaust when you drop the red line, put in a hand valve to dump it or yes shunt will work - that just effectively tricks the emergency relay valve into thinking the red line is attached.If you are fabricating brackets they will have to be very substantial even the factory mounts flex alarmingly under full pressure. They might be ok to start with but you can easily find welds or even the metal cracks further down the line.

To be honest if you’d gone for drums chances are the air over hydraulic chambers would have been a straight bolt on too late now though, obviously.

I did follow on the load sensing. I am sure it must use bag pressure for the air and hydraulic combined valve as yes with self-levelling the suspension will never move.

I understand the project element but this really does not make sense, to my mind, you would be much better investing the time and money in fitting all potential tow vehicles with an air capability which would mean they could then tow any standard drawbar or artic trailer with a dolly rather than the other way round.

I must admit I’m going off the idea of bothering with hydraulic brakes at all, I’m not worried about fabricating the brackets, I can do that, but it’s just one more thing to do. £300 for a set of brake chambers and probably another £100 to have brake lines made up. Could add air on to the one tractor we have that doesn’t have air but that is likely to be replaced next year, so I suppose it can just wait, still have another trailer to use with that tractor for now. Wish I’d bought a trailer with drum brakes but really didn’t expect this to have disc brakes!

With self leveling air suspension, yes, a load sensing valve must use bag pressure, all of the load sensing valves I’ve seen will probably be designed for steel suspension trailers. Again, steel suspension may have been simpler but on air it should ride very nicely. also helps being able to drop the trailer for loading. Will be considering air brakes only now, but getting rid of the spring chambers, I don’t need them and they’ll only annoy me, having to hook up the air lines and wait before tanks fill before I can just move it across the yard. Also think there’s less chance of problems without the springs. Now to work out how to disassemble the chamber without injuring myself ![]()