Gingerfold:

Newmercman:

[ZB]

Anorak:

It looks as if Leyland Motors was doomed, even before it was saddled with a loss-making car division or a poisoned shopfloor. The decision to wind down sales efforts in the European market, coupled with a tardiness in employing properly-qualified personnel in the engineering offices, was already bearing fruit with the undersized Ergo, Power Plus unreliability and badly-executed 500 series. If anything, its management in the 1970s and '80s deserves some credit for keeping it going as long as it did. Against this backdrop of 25 years of incompetence and sabotage, to replace the Ergo range with something as competitive as the T45 seems miraculous.

I said it a few pages ago, with all that was going on it was a wonder that they managed to keep the company afloat as long as they did

Yes a fascinating period to look back on. Just by considering what has been contributed on this thread it is a miracle that anything got produced at all that even worked!!

I think that there was an OHC fixed head engine produced by Leyland in the 1930s, so as Valkyrie states the idea was not new. What was new about the 500 series was that the gear train for the camshaft etc. was at the flywheel end of the engine instead of the front of the engine, something to do with fewer “nodal stresses” (whatever they are?). This is now common practice on modern engine designs.

Best Ergomatic Cabbed-Lorry Model? PART 11.Page 19.TRUCKNETUK

LEYLAND 500-SERIES FIXED HEAD HEADLESS WONDER DIESEL ENGINE,OR THERE IS NOTHING NEW UNDER THE SUN.

In regard Gingerfold’s comments.Well,that grand old and true saying :“There is nothing new under the sun”  ,strikes again

,strikes again

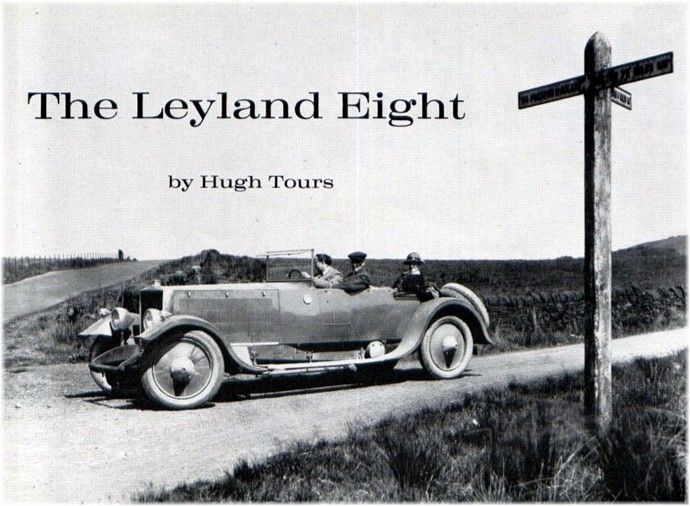

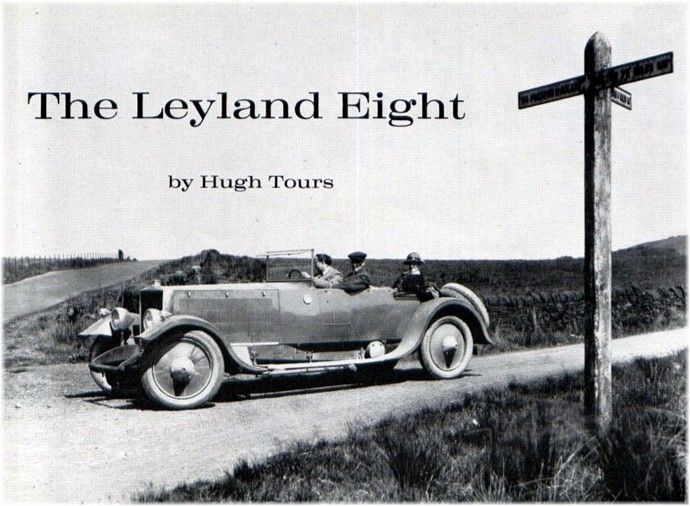

As far as I know,Leyland probably did make fixed cylinder head petrol engines for their motor vehicles in the 1900s and teens of the 20th Century,but by 1920 all engines probably had detachable cylinders heads.The Chief Engineer of Leyland Motors at that time was the famous J.G.Parry Thomas,who designed and masterminded Leyland’s version of a luxury motorcar that was a rival of the Rolls-Royce motorcar marque.And,by all accounts,the Leyland Eight was a superb design that at least some people thought was better than a Rolls-Royce!

It’s straight eight overhead camshaft engine,with a detachable cylinder head, was originally

of 6967 cc (89 x 140 mm.) capacity,but was enlarged to 7266 cc (89 x 146 mm.) and produced 145 BHP,with an RAC HP rating of 40 HP.NOT ONLY THAT,but the eccentric-driven overhead camshaft

was driven from timing gears at the back of the engine!  So the rear-mounted gear train for the

So the rear-mounted gear train for the

camshaft predated the Leyland 500-Series engine by around 38 years!

The front end of the Leyland eight-cylinder engine’s camshaft drove the waterpump.

The expensive Leyland Eight went on show at the Motor Show of 1920 at Olympia,and was known

as THE LION OF OLYMPIA,and eighteen were made from 1920 to 1923

Leyland Eight 7.2 Litre Luxury Motorcar of 1920-1923:-The Lion Of Olympia:-

The engine of the Leyland Eight must have influenced later engine designs for Leyland lorries,

buses and motorcoaches from the late 1920s and onwards:Overhead camshaft petrol and diesel-oil

engines powered Leyland Titans,Tigers,Beavers,Octopus’s,etc.But these engines had detachable cylinder heads and the camshaft drives were at the front of the engines.

Other engines that had rear positioned camshaft drives were:-

Daimler CD6,CD6S,CD650,CD650H diesel engines for motorcoaches and buses.1945-1965.

Dennis O6 diesel engines for buses and motorcoaches,1945-1962,and lorries.

Meadows 6DC630 diesel engine for lorries,motorcoaches,buses,etc.From 1946 to 1969?

They may well be other engines that have rear positioned camshaft drives - I do know that

the Gardner 6LYT - examples of the original design - do…the later re-designed 6LYT

has a front-located camshaft drive.

And here is a very telling piece from BIGLORRYBLOG about the anything but precision-made and disasterous

Leyland 500-Series Fixed Cylinder Head Headless Wonder Diesel Engine

:-

:-

It’s that Leyland Buffalo moment says Biglorryblog. Let’s hear it for the fixed head engine…or not

12 July 2007

By Biglorryblog

Buffaload2.jpg Obviously the irony of this headline probably escaped the copywriter for this Leyland Buffalo 2 ad from 1979. Good truck better? Let’s face it, given all the problems Buffalo had with the famous (make that infamous) fixed-head 500 engine it probably couldn’t have got any worse! No doubt operators rushed to buy the Buffalo with the TL11, which I think was based old Leyland 680 six-pot (though no doubt my trusty BLB army will tell me if I’m wrong).

The late, and sadly-missed Graham Montgomerie (ex-engineering editor of Commercial Motor) once told me that as a young Leyland technician one of his jobs was to find out why the fixed-head engine kept seizing up. So they took a bunch of engines into the test lab and tried to get them to mis-behave. Only to everyone’s amazement they all ran perfectly. It wasn’t until later that Graham realised that the engines they’d been given were effectively ‘blue-printed’. When they checked the tolerance on the production engines they were all over the place–hence their appalling durability. I certainly remember riding in a Buffalo 2 on a CM roadtest. It was the first time I’d ever been in a truck. (My back has only just recovered…)

VALKYRIE

further discussion.

![]()

![]()

![]()

![]()