Wheel Nut:

removalboy:

Not realy knowing much about curtainsiders… don’t they have straps attached to the roof that you tie around pallets or something

If so then there isn’t realy much of an excuse.Roof straps are only really of any use to hold light loads like packaging materials or well shrunkwrapped pallets like bottles or jars. You cannot use them to secure machinery or IBC, drums, or MDF / Chipboard.

A curtainsider is always going to be a compromise, operators want them as light as possible, unhindered access, as much deck space as possible and as high as possible door aperture whilst still keeping under the 4.0m height limit (for Euro operations)

The problem with using roof straps, spider straps or longitudinal straps are that you need a secure fixing point, so unless you are willing to put up with extra weight centre posts or central roof supports the cant rails will bend, the front and rear bulkheads will be pulled towards each other. Until they invent skyhooks, the only secure way to fasten any load to a trailer will be to the chassis or the weight bearing members of the floor.

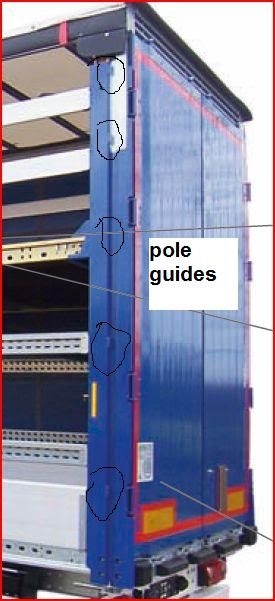

While I am on my soapbox. I often read about curtainsider poles being bent and ratchets broken, well that probably comes from drivers who do not really understand what the curtains are doing. The aluminium or originally wooden poles need at least one turn of material on them, the poles have to be located in the top and bottom correctly and also behind the guides on the uprights before tensioning.

Some are different and only have one guide in the centre and some use a more solid bar but the principle is the same, the tensioner turns the pole that in turn makes the curtain taut, not taut like a banjo string, just enough to stop it flapping which may even save you some money in fuel

I have seen drivers with an extension or a large spanner trying to get more leverage to tension the curtain till it is at literally breaking point

Thanks for explaining that. ![]()

![]()