Evening all, now its getting interesting, sort of going backwards to answer some of he comments,

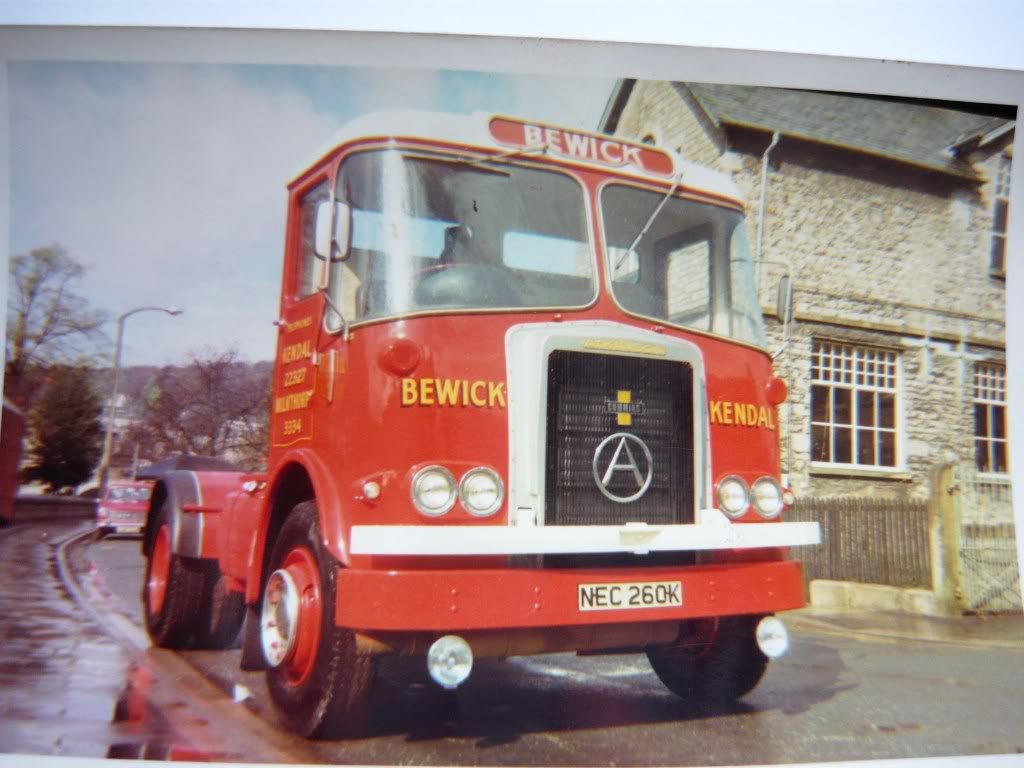

Larry, our family had an S36, 680 Leyland, that had a Kysor shuter, purchased second hand, (and I cannot remember the original owner). But someone who obviously had specified his vehicles well. We thought it a real “powerhouse”, and the vehicle was a one driver machine, but what a goer! I would have thought that such a shutter would have produced better operating temperature if fitted to a Gardner, but how to overcome the oil cooler? someone must have retro fitted one to some chassis. Dennis, (Bewick), I seem to recall fitted shutters to some of his Seddons, but I do`nt think that they were Kysors, or Gardner powered. Perhaps he could enlighten us?

Mark those are really interesting points from across the Atlantic. That “magic coating”, for wearing parts, was, ( If my memory is correct), marketed here as “Slick 50”, or some similar name, in the 80s. The procedure was to firstly drain, then flush both engine and gearbox, add the requsite quantity of “the potion”, then refill with lubricant. The idea being that the (silicon base)? would coat the wearing parts, and promote long life!

I recall that operational trials were carried out, either under the scruitiny of Motor Transport, (John Aldridge)■■ or the IRTE magazine. The operator was an own account one from the West Country, running drawbar Seddon 400s, (but the little grey cells do not recall the name, although I can recall the photograph that fronted the article, (boy I now realise that I am ageing)!!!

I seem to recall that driving two comparative lorries, one treated, one untreated, and another that had the gearbox treated, there were real differences in operation, favouring the "treated " lorry in each case.

Anybody have hands on experience, or can add more detail??

I presume that the grand daddy of all these treatments was STP??

cav551,and windrush, quite rightly cite the advantages that Gardner designs had over their competitors particularly in the area of cylinder head design. I seem to recall that one of the areas of concern that Brian Veale of Shell Mex BP had to address was the difficulty of replacing 7.7 AEC head gaskets, and water pumps, as both failed on a regular basis. The SM, BP modification being an alteration to the access via the cab, and cab front panel. Apparantly the standard “factory” access being somewhat “tight”!

I can identify with cav551s comment about US insrumentation. Many of the tractors that I imported had the full VIT interior package, chrome steering column, pedal arms, gearstick(s), buton back naugahyde trim, ( a sort of gloss plastic, mainly in abbattoir scarlet Oxblood, or Funeral parlour deep blue)!!! (not to be sat in following a night on Banks`s mild, or any other heavy beer)!! Plus of course a myriad of indistinguishable small gauges covering every intimate function of the vehicle, whether you needed to know, or not! Now as a source of paranoid panic, these little gems have never been beaten. Picture this, you are cruising along at great velocity, the long bonnet out ahead, then you glance down, and of course your eye catches one needle. It may be doing a little dance, or it may look odd…and of course you have never noted this needle before!!! The enjoyable day is disrupted, whats wrong■■? Now, in hindsight I can say, probably nothing!!!. Pyrometers, front diff temperature, second diff temperature, oil flow, temperature, pressure, …the dials of nightmares, you become fixated upon impending doom…not the fact that it was probably the antics of old electrics, on an old vehicle!!

I shall away to my “theraputic” Bollinger, and see if it can repair my little grey cells, enough to remember the correct name for that product, and more importantly the operators name!!

One final thought, for us lorry men to ponder, why is it that some of the finest commercial vehicle, and road transport engineers, have a background in Bus engineering■■? An interesting point is it not!!

Bon nuit mes braves, Cheerio for now.