Best Ergomatic Cabbed-Lorry Model? PART 20.Page 30.TRUCKNETUK.

First of all I must reply to the incorrect comment by Cargo:-

Quote:-“No company could keep its head above water while offering so many similar models in

direct competition with each other.”

VALKYRIE replies:Multi-marque companies have far bigger market shares and profits than single

marque companies.This objective fact was proved by the Leyland Motor Corporation in

the 1950s,1960s and 1970s,and other motor corporations have also proved it,and are still proving

it!

And now for the main event:-

As I said in my Post 19,page 28,in this thread on Monday,20th May,2013:“With this newly acquired

information,I will hopefully deal with the Leyland 700-Series and 500-Series Fixedhead Diesel

Engines in my next post  ”

”

So here we go:-

LEYLAND 700-SERIES AND 500-SERIES FIXEDHEAD -HEADLESS WONDER- DIESEL ENGINES.

First of all,I will have to repeat the major points again:-

1.Both AEC and Leyland diesel engines were prone to blowing cylinder head gaskets.

2.According to the former secretary of the British Leyland Truck & Bus Division and author of

several books on the history of Leyland motorcoaches and buses,Doug Jack,British Leyland’s

Director of Engineering,Albert D.Fogg,influenced by the five-times Le Mans Motor Race-winning

Bentley fixedhead motorcar engine,Albert formulated the Leyland 700-Series fixedhead diesel engine.

3.The Leyland 700-Series fixedhead engine would eliminate cylinder head gasket issues once and

for all!

It would also improve engine cooling,because there would be no cylinder head retaining

It would also improve engine cooling,because there would be no cylinder head retaining

bolts disrupting water passsages and the flow of cooling water.

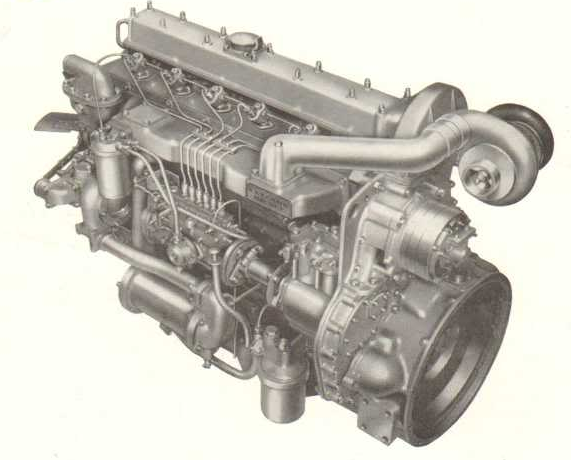

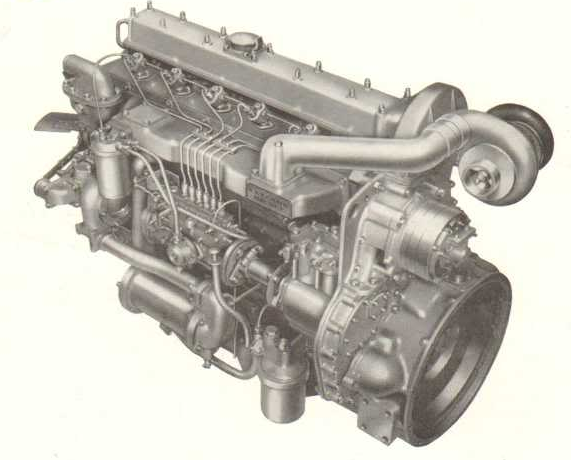

4.The 700-Series had a capacity of 700 CID - 11.4 litres,a single overhead camshaft which was

driven by a timing gear train that was mounted on the rear of the engine.

5.Here is some of what I said in my Post 16:-

“Albert Fogg developed this engine,and when the Leyland marketing men called for the engine to be

reduced in capacity to 8.2-litres because supposedly it was too heavy and too physically

large,and had to weigh less than 1000 Kgs  ,Albert Fogg walked out of Leyland!

,Albert Fogg walked out of Leyland!

He

He

must have known that a 500 CID engine was just too small and was not fit for purpose to work in

32 ton GTW lorries

I also state in Part 10 that this sudden reduction in engine capacity resulted in quality control

problems in the production of these engines  ”

”

LEYLAND 500-SERIES AND 700-SERIES ENGINES - NEW INFORMATION.

A.Apparently,there were two versions of the Leyland O.400 Comet Diesel Engine:One had a U-Flow

cylinder head and the other had a Cross-Flow cylinder head.This cross-flow version in the Comet

and Super Comet lorry range was not reliable:It kept blowing cylinder head gaskets,so Leyland

came up with an uprated version of the O.400 which had a u-flow cylinder head which largely

eliminated the blown gasket problems

B.Leyland engineers looked in to the future and saw that it was turbocharged,but they didn’t

have much confidence in producing turbocharged versions of the O.400,O.600 and O.680 engines

because of all the blown cylinder head gasket problems.

C.This new information does not mention Albert Fogg by the way.But it does mention the same

things that I mentioned in my previous post,No.19:Ergomatic-cabbed AEC,Albion and Leyland

lorries had cooling problems and this harmed export sales.This new information goes on to say

exactly what I said in my above point 3,but it goes further on to say that improved cooling

would result in longer valve life-engine life,and,if it was a fixedhead engine,it would reduce

machining costs.

D.Again,I’ll quote myself from my No.16 Post:"So obviously,Leyland had planned the 700-Series

to,maybe,replace the 0.680 engine,but jumped on the Volvo and Scania small capacity engine

bandwagon by turning it in to the reduced capacity 500-Series

But why didn’t Leyland produce the engine in two model-sizes?  :The 500-Series and 700-Series

:The 500-Series and 700-Series

But Leyland Truck and Bus was starved of money  ,so Leyland,although it had a new 8.2-litre

,so Leyland,although it had a new 8.2-litre

engine,it seriously lacked a brand new 11-12-litre engine  ,which should have been the 700

,which should have been the 700

-Series,so Leyland could properly compete with the similar sized engines of ■■■■■■■■■■■■■■

Royce,AEC,Volvo,etc  …but,on the other hand,as [ZB] Anorak says,there were the AEC

…but,on the other hand,as [ZB] Anorak says,there were the AEC

11.3,12.47 six-cylinder,and AEC 800-Series/801-Series V8-cylinder,plus the Leyland 680 and 690

11.1-litre six-cylinder engines

E.Well,actually,this new information says that the 500-Series engine was designed to replace

the O.400 engine  …and,oh yes!

…and,oh yes!

…a 700-Series engine was planned to replace the O.680

…a 700-Series engine was planned to replace the O.680

engine!

…Single-cylinder turbocharged pilot engines were built and tested,and these highly

…Single-cylinder turbocharged pilot engines were built and tested,and these highly

turbocharged engines passed the tests

F.The maximum power output of the 500-Series turbocharged engine was predicted to be 260 BHP,so

the misguided Leyland Product Planning Division foolishly began questioning the need for the

700-Series engine - bloody short-sighted fools!

Thus they very misguidedly dropped the 700-Series

Thus they very misguidedly dropped the 700-Series

engine - due to cost cutting no doubt  - and decreed that the 500-Series at 170 BHP should replace

- and decreed that the 500-Series at 170 BHP should replace

the O.400 in the Comet,a 200-220 bhp lightly turbocharged version would replace the O.600 and a

turbocharged 500-Series 260 BHP engine would replace the O.680 engine  Leyland’s product planning

Leyland’s product planning

misadventure failed to take in to account the 10 to 15 and more litre engines of Leyland’s

rivals!

My new information reveals that the above decree was controversial within Leyland,which

My new information reveals that the above decree was controversial within Leyland,which

of course,included Albert Fogg’s decision to resign from his various positions in British Leyland

because of the axing of the 700-Series engine

G.After extensive work on trying to find a solution to the engine cooling problems in Ergomatic-

cabbed lorries,it was concluded that it was the poor engine installation design of the Ergomatic

cab that caused the cooling problems -please SEE My Post 19.It had nothing to do with cylinder

head and gasket design.Work on testing turbocharged O.400 and O.680 engines started up again.

H.If the poor engine installation design of the Ergomatic cab was bad for AEC and Leyland

engines,it was even worse for the 500-Series engine - this engine would NOT FIT!

It was

It was

discovered that the 500-Series engine designers had used the LAD cab floor dimensions,NOT the

Ergomatic ones,to set the installation measurements of the 500-Series engine!

Just what the hell

Just what the hell

were they playing at?!!!

There was no way to get around it,the Ergomatic cab was already tooled up and had been in

production for two years already,so major design changes to this cab just could not be made.

I.There was no way around the above problem,except to raise the cab by 5 inches,so all the

Leyland lorry models in the 500-System had Ergomatic cabs that were 5 inches higher,compared to

the Leyland Freightline Ergomatic cabs.The raising of the cab introduced further problems,but

these were eventually resolved.

J.The Leyland 500-Series engine was a commercial and engineering disaster,the late great Pat

Kennett said the engine had a rejection rate of 60%!

and warranties were very high

and warranties were very high  :-

:-

1B.The rear timing gear train was intended to allow rear-mounted engine auxiliaries and service

access,etc,at the front,but for some reason or reasons,it was not successful and a front-mounted

gear train was added to drive the cooling fan and some other auxiliaries

2B.The building costs of this engine were far,far higher than the O.400 engine,and,as I’ve

already said several times in this thread,manufacturing quality ranged from good to mainly

terrible - as I say:60% rejection rate

3B.All of the following problems showed up in service:The housing for the rear-mounted timing

gear train was not stiff enough and caused “engine bending”,noise and vibration.The engines

used to go stiff - some would seize up,and so on,and so on

4B.So much money was spent on 500-Series engine warranty payouts,modifications in trying to get

the engine to work properly that management would not consent to development work on the O.400

and O.680 engines,so the engineers had to do this work in secret  Furthermore,the cost of a 500-

Furthermore,the cost of a 500-

Series engine was higher than,say an O.680 engine,and this gave Leyland’s rivals a price

advantage

THE LEYLAND 8 TO 11 ENGINE PROGRAMME - THE IRONY OF IT ALL.

So Leyland carried on…on the Leyland 500-Series Engine Rocky Road,poor engine manufacturing

quality,engine seize ups and all  But in 1976,there were changes in Leyland’s top management and

But in 1976,there were changes in Leyland’s top management and

the Leyland 8 to 11 Engine Programme was started:The scrapping of the 500-Series engine in favour

of a revised and uprated O.680 engine,the TL11A  This turbocharged engine was powerful and

This turbocharged engine was powerful and

smooth-running,and not only powered Leyland lorries,but also motorcoaches and buses and was

further developed to produce 245 BHP and then 260 BHP  - notably for motorcoaches and buses

- notably for motorcoaches and buses

It was one of the best pure Leyland engines that Leyland ever made  ,and should have been made

,and should have been made

from the late 1960s at least instead of wasting money on the 500-Series Engine fiasco!

It was really ironical

LEYLAND 500-SERIES FIXEDHEAD HEADLESS WONDER DIESEL ENGINE - A FIASCO:-

…and one of it’s victims  - a representative example…the engine change says it all

- a representative example…the engine change says it all  :-

:-

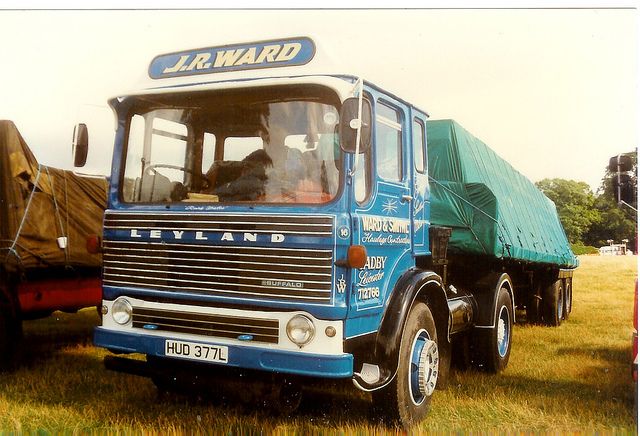

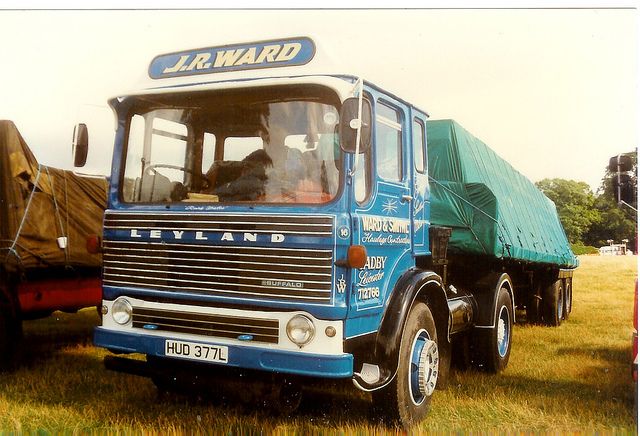

LEYLAND BUFFALO 500-SYSTEM 4x2 FLAT-BODIED ARTICULATED LORRY,HUD 377L.1972.It originally had a

500-Series 510 engine,now has a TL11A engine.Preserved  :-

:-

Leyland TL11 260 BHP Diesel Engine IN EXCELSIS!

:A silky smooth running and sounding,powerful

:A silky smooth running and sounding,powerful

and very reliable Leyland TL11 260 BHP Diesel Engine powers this magnificent motorcoach  :-

:-

LEYLAND TIGER 260 TRCTL11/3RZ/DUPLE 340SL C51T MOTORCOACH,Chassis No.8700022,Body No.8795/0452,

Reg E52 URH,KINGSTON STAR.Previously registered 152 FRH and 834 EYD.March 1988.East Yorkshire

Motor Services No.52.Sold to Motorcoach Leasing in 1999:-

DAIMLER Motor Vehicle Marque.Yes.The splendid ex-British Leyland Daimler marque is the eighth

marque to have the last say so far:-

WHAT?

WHAT?

!Another motorcoach and bus marque?

!Another motorcoach and bus marque?  I here you say. Well,this Post No.20 will reveal that besides motorcoaches and buses,Daimler

I here you say. Well,this Post No.20 will reveal that besides motorcoaches and buses,Daimler

also made lorries  - one lorry model was quite spectacular!

- one lorry model was quite spectacular!

- and the company had a brief

- and the company had a brief

agreement with AEC…Daimler also continue to make high quality luxury motorcars

DAIMLER MARQUE MOTORCOACH AND BUS BADGE:-

DAIMLER COMMERCIAL VEHICLES AND AGRICULTURAL TRACTORS Stand No.236,R.A.S.E Show,Wollaton

Park,Nottingham,Summer 1915.Daimler Y-Type Lorry on the right:-

DAIMLER CB,FLAT-BODIED,2-TON 4x2 LORRY,PW 104,1915.Watts,Lydney:-

Daimler made the spectacular Daimler Renard Roadtrain - Road Locomotives,which pulled 3-axle

drawbar trailers,the middle axle of each trailer was powered by a series of universally-jointed

power shafts.The front one of which was connected to the road locomotive’s transmission system,

so these shafts went from trailer to trailer.The Daimler Road Locomotive was powered by a Daimler

Knight 16.1-litre sleeve valve 6-cylinder 80 BHP petrol engine.

roadtrains.com.au/article_ar … ticleId=79

DAIMLER RENARD ROADTRAIN - Road Locomotive and three powered drawbar trailers in preservation:-

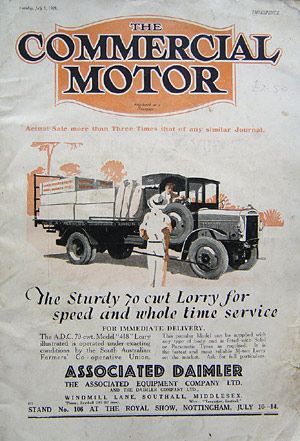

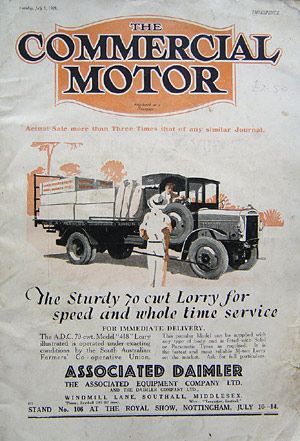

AEC and Daimler entered in to a marketing agreement under the ADC = Associated Daimler Company

name.

AEC and Daimler.ASSOCIATED DAIMLER Commerial Vehicles advertisement,showing an ADC - Associated

Daimler Company Sturdy 70-CWT Lorry model.1926-1928 - that’s how long Associated Daimler lasted:-

ASSOCIATED DAIMLER 416A/WYATT C30D MOTORCOACH,BR 6496.1928.Northern General D376.Preserved.South Yorkshire Transport Rally 2011,Meadowhall Shopping Centre Motorcoach Park,Sheffield:-

ASSOCIATED DAIMLER 802 LS/EAGLE ENGINEERING 6x4 9-TON HEAVY BREAKDOWN TENDER HEAVY RECOVERY

VEHICLE,one of four ex-L.G.O.C.LS Class double decker buses converted in to HRV’s:-

ASSOCIATED DAIMLER 802 LS/EAGLE ENGINEERING 6x4 9-TON HEAVY BREAKDOWN TENDER HEAVY RECOVERY

VEHICLE,one of four ex-L.G.O.C.LS Class double decker buses converted in to HRV’s -

1.Chassis No.802015,Reg UC 2299,BT 219U,ex-LS6.

2.CN.802017,Reg YW 7989,BT 220U,LS8.

3.CN.802011,Reg UC 2201,BT 221U,LS3.

4.CN.802018,Reg YW 7986,BT 222U,LS10.

Portrait-painting profiles:-

Daimler is better known as a luxury motorcar manufacturer,and at one time was THE choice of

motorcars for the British royal family,and the royal families of other countries  :-

:-

DAIMLER DOUBLE 6-50,6.5-Litre OHV V12,ROYAL STATE LIMOUSINE.1935,King George V.Front nearside

view.India.In 1947 it was bought by the Maharaja of Darbhanga.Now owned by car dealer Sharad

Sanghi:-

DAIMLER Mk2 4x4 ARMOURED CAR,British Army,WW2:-

DAIMLER CVD6SD/DUPLE A-TYPE FS1 C35F MOTORCOACH,ORB 277,JULY 1950.Blue Bus,Willington

DR12,BAMMOT,Wythall:-

Jaguar needed increased motorcar production capacity by 1974,so they started producing cars in

Daimler’s Radford,Coventry,factory and transferred Daimler Fleetline bus production to Leyland.

Last Coventry-built Daimler Fleetline-

Daimler Fleetline CRG6LX,Metsec WO6 H61,41D 102-Seat Double Decker Bus,Chassis No.67993,BG 1223.

March 1974. China Motor Bus Company LF14:-

Sadly,I cannot find a photograph of the complete omnibus,but I have found a photograph of the

last but one Coventry-built Daimler Fleetline  :-

:-

Daimler Fleetline CRG6LX,Metsec WO6 H61,41D 102-Seat Double Decker Bus,Chassis No.67992,BG 3635.

May 1974. China Motor Bus Company LF30.The last but one Coventry-built Daimler Fleetline:-

Production details:-

67992 CRG6LX-33 BG3635 Metsec W06 H61/41D 5/1974 China Motor Bus LF30

67993 CRG6LX-33 BG1223 Metsec W06 H61/41D 3/1974 China Motor Bus LF14

There is no wonder why I’m doing tributes to British Leyland marques!  Because,in common with all

Because,in common with all

of the other marques,the Daimler marque name was criminally dropped!!!

This kind of ludicrous and callous act rightly put people off Leyland and all it’s works!!!

This kind of ludicrous and callous act rightly put people off Leyland and all it’s works!!!

The Daimler name survived on motorcars  ,but was replaced by the Leyland name on DAIMLER bus

,but was replaced by the Leyland name on DAIMLER bus

models

DAIMLER.Last Daimler (“Leyland”) Fleetline to be built-Daimler Fleetline FE30ALR/ECW H44/31F 75-

Seat Double Decker Bus,Chassis No.8002356,Body No.25067,SCH 117X,1981.South Notts 117,then

Hulleys 20:-

The Daimler CB,CC,CD,CK,etc,were built for multi-purpose use,suitable for bus and lorry use,as is shown in the next photograph,below.

100 Years of Motorbuses in Sheffield 1913-2013,and the first bus to be operated by Sheffield

Corporation happened to be this Daimler bus  :-

:-

DAIMLER,SHEFFIELD.First omnibus to be bought by Sheffield Transport,

Daimler CC419/Dodson OT18/16R 34-Seat Double Decker Bus,W 3201,1913.Sheffield No.1  :-

:-

So it was appropriate that the last bus that entered service with Sheffield Corporation was the

Daimler bus below in 1973.South Yorkshire Passenger Transport Executive took over bus and

motorcoach operations from April 1974  …and the glorious Sheffield light cream,azure blue

…and the glorious Sheffield light cream,azure blue

relief,livery gradually disappeared…which was scandalous!!!

DAIMLER,SHEFFIELD.Last omnibus to be bought by Sheffield Transport -

Daimler Fleetline CRG6LXB/Park Royal H43/27D 70-Seat Double Decker Bus,Chassis No.67602,WWJ

754M,1973.Sheffield No. 754.Preserved.Seen at Sandtoft Transport Centre,near Doncaster  :-

:-

VALKYRIE

![]()

![]() .

.![]()

![]() .

.